A guide to BOPP labels and their best uses

Contact us to discuss your requirements of flexible printable bopp film quotes. Our experienced sales team can help you identify the options that best suit your needs.

Other articles you might like:

Biaxially oriented polypropylene, commonly known as BOPP, plays a vital role in our daily lives. You&#;ve probably encountered BOPP labels on various food packages, but they&#;re also found on product labels across a wide variety of industries. In this article, we&#;ll explore what BOPP is, its characteristics, and the diverse applications where you can utilize these versatile labels in your business.

What is BOPP?

BOPP refers to the manufacturing process of the material. The raw materials are melted and spread onto cylinders where they are rapidly cooled. The material is then stretched in two directions to reduce its thickness as well as increase its flexibility and strength.

BOPP is generally manufactured as a film on rolls, making it easy to store in large quantities. Before the final rolling, the film receives the flame or corona treatment, making it suitable for the application of inks, adhesives, or metals.

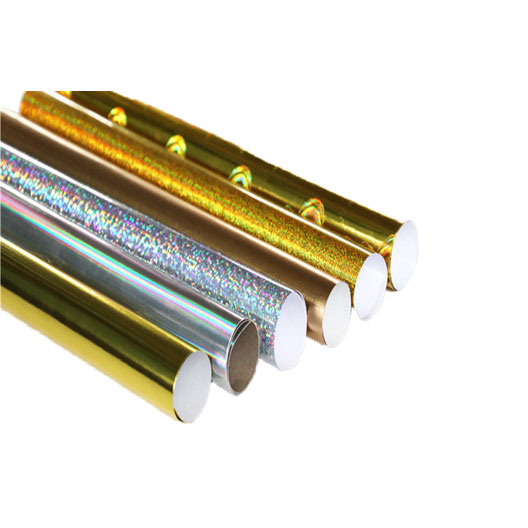

Available from Avery WePrint, our professional printing service, in matte white and glossy white and matte and glossy clear to holographic and metallic, you can find the ideal BOPP label for your products and packaging. You can also find many BOPP labels that you can print yourself.

The benefits of BOPP

BOPP is incredibly versatile. You can order BOPP labels in opacities from clear to white to metallic, making it a great option to enhance your product branding. Whether you choose metallic for a unique look, clear for minimalism, or white for traditional, BOPP labels always provide a good first impression.

Ideal for printing

The film material takes both water- and solvent-based inks well, which allows your printing service more options when using BOPP for your product packaging. It takes ink well due to its final treatment, which generally enhances the printability and ability of ink to stick to the material.

Resist water, oils, chemicals and UV rays

Since the material is plastic-based and durable it resists most intrusive liquids and oils. Even if your products are not in a refrigerated case where liquid tends to be, something spilled on your products won&#;t smear or ruin your label if using BOPP. Resistance to oils is vital for not only oily products but also means you don&#;t have to worry about hand oils or lotions smearing the ink.

BOPP is also ideal in industrial as well as outdoor settings. The resistance to chemicals and UV light, as well as the long-lasting nature of the product, ensures safe labeling with no fading during the service life of your product.

Flexibility

BOPP film is remarkably flexible. It works just as well-rounded containers as it does on flat surfaces whether hand or machine-applied. Since most BOPP film is incredibly thin, it can look like you printed directly on product bottles and jars. This extra touch can help set your products apart on the shelf.

Durability

BOPP is often thought of as one of the most durable label options on the market. Its various properties make it immune to many common problems, such as lifting, peeling, and wrinkling. BOPP labels are meant to last, regardless of where you use them.

Eco-friendly

BOPP films have a relatively low carbon footprint compared to other plastic substrates such as polyester. Since it has a low melting point, it takes less energy to convert from one form to other.

Where to use BOPP labels

Next to paper, BOPP is the most popular material for labels. Its proven performance and affordability make it the preferred label material for a variety of industries. BOPP labels have many uses, and you can find the film in almost any business sector. Even in your personal life, you see BOPP labels on a variety of consumer goods around your home as well as in public.

Food & beverages

BOPP is a superstar in the food sector because of its waterproof, moisture-barrier properties, sealing ability, clear graphic reproduction, and shelf appeal. It is a favorite label material for all kinds of food and beverage containers. Even when it&#;s not in direct contact with food, it holds up to processes like off-gassing from acidic foods that leave other label materials stained or smeared.

Beverage bottles can be tricky to label due to the round surfaces and varying bottle textures. Along with the advantages above, the thinness of BOPP film allows for a great deal of flexibility when you&#;re applying it to glass and plastic containers. BOPP clear labels can give your beverages a seamless, printed-on look.

Health and beauty

Cosmetics and wellness items require specific labeling information and you need a material that holds up in damp or humid environments. Along with all the benefits mentioned in food and beverage labeling, BOPP is perfect for health and beauty items due to its resistance to the product inside, oils from hands, and water from sinks or showers. All of these things BOPP can handle.

Medical facilities

All medical items require labels that stand the test of time. Even on disposable medical equipment, a label can help someone get the necessary care. If you&#;re in the medical field, you should consider BOPP labels.

The labels are immune to chemicals and liquids that would smear other labels. Plus, the durability of the labels makes them a good choice if you make medical supplies that might be stored for extended periods of time.

Other industries that use BOPP labels

- Horticulture & Nurseries

- Lumberyards

- Shipping

- Barcode & Warehouse Labeling

When you&#;re ready to buy

There are a variety of benefits to using BOPP material. But to make sure you choose the ideal material for your products and packaging reach out to our label experts at Avery. As the inventors of self-adhesive labels, we will happily help you find the best label for your packaging. Contact us at 800-942- to learn how we can help you enhance your branding.

Author:

If you are looking for more details, kindly visit tenter process bopp film.

Explore more:Understanding Recyclable Shrink Films: Polyolefin vs ... Melanie Neff

What Size Tarp for Camping?When Should You Consider Using Eco-Solvent Ink for Your Printing Projects?Water Bottle Sport Cap: Enhancing Hydration On-the-GoAdvantages and Applications of Sticky Sublimation PaperWhich Types of Glass Liquor Bottles are Commonly Used in the Beverage Industry, and Why?How do you know if a plastic bucket is food grade?

Melanie has an extensive writing background built on an impressive journalism foundation. As a reporter for USA Today and The Los Angeles Times for almost 20 years, she covered everything from the Los Angeles riots, fires, and floods to LA Lakers, Raiders and Clippers games and movie premieres. She followed her newspaper career with a long tenure covering commercial real estate financing and development.

Melanie has been writing about small business marketing and labeling needs for the last 12 years. She thrives on reading, researching and expanding her knowledge of everything going on in today's business world and looks to provide the most valuable information she can to her readers.

View all posts by Melanie Neff

Biaxially Oriented Polypropylene (BOPP) films are frontrunners in the food packaging space, thanks to their exceptional moisture barrier properties. Foods that are sensitive to moisture require an adequate barrier to retain their crispiness and maintain shelf life.

Even better, BOPP films are biodegradable and completely non-toxic, making them eco-friendly. The best part, these films are inexpensive and substantially reduce overall cost. In addition, BOPP films have made handling, containments, and shipping of foods effortless, from pouches to packages.

But there&#;s more to it. Companies and brands are actively digging ways to improve the aesthetic appeal of BOPP films so that the packaged product looks as good as it tastes. Since it&#;s the package and its aesthetics that directly hits the customer, a lot goes into the final outlook of BOPP films. Factors like ease of use, user-friendliness, brand identification, film quality, and print are crucial from the customer&#;s standpoint.

So even though the film has all it needs to sustain perishable products, it&#;s the final print that means the most. This is where BOPP printing comes in. Understanding how BOPP films are printed, the different technologies used to print these films can help better understand what method works best based on film properties, budget, design, and graphics.

Read on to find more about the printing processes for BOPP films.

Printing Processes for BOPP Films

BOPP film can be printed with one or more of the following processes. Each of these uses unique technology and serves a particular purpose.

Flexographic Printing

Flexographic printing uses flexography, a famous printing technology that uses a flexible printing plate. In fact, flexography is by far the most widely used print technology in the label industry. It has evolved through the years. Modern flexographic machines employ flexible photopolymer printing plates that are wrapped around cylinders onto a web press. Both water-based inks and UV inks can be used with these printing plates. These plates rotate at high speeds, transferring the ink through tiny holes to the film. Newer flexographic printing machines enliven texts, graphics, and images and print at a high line count.

Pros

- Flexographic printing is a high-speed process and is ideal for long printing runs

- It is suitable for a range of substrate materials

- The process requires minimum time to set-up

- It causes minimum waste during printing

- Multi-purpose system as it does printing, varnishing, laminating, and die-cutting in one go

- Modern flexographic printing methods are fully controlled and require less operator on board

- Produces high quality print

- The equipment requires minimum maintenance

- It requires inexpensive equipment

Cons

- Overall, the estimated price of flexographic printing plates is higher than other printing forms. However, with adequate maintenance, these plates can last for a very long time.

Rotogravure Printing

Rotogravure printing utilizes the traditional rotatory print technique to print on BOPP films. This method revolves around printing directly on a cylinder, plate, or any similar substance. The imprint is then transferred onto the final substrate, which in this case, is the BOPP film. Rotogravure printing is highly popular in large-scale commercial printing of BOPP-film pouches and containers.

Pros

- The production speed of rotogravure printing gives it an edge over other printing methods. Rotogravure printing has the ability to reach a very high speed.

- The print quality of images and graphics with this method is consistent.

- The print cylinders used in the rotogravure printing method can be repeated several times.

Cons

- The start-up cost of the rotogravure printing method is exceptionally high, and a very high print output is needed to make up for the initial investment.

- The preparation time of cylinders is time-consuming as it requires a specific skill set.

Digital Printing

Digital printing of BOPP films is based on the ink-jet print method. However, unlike other printing methods, the images and graphics in digital printing are directly transferred onto the BOPP film substrate. Due to this, digital printing can cater to a wide range of audiences and is also super fast. What&#;s more, digital printing does not require any cardboard inserts or labels.

Pros

- Suitable for printing dynamic content for a different group of audiences.

- It is a fast process.

- Digital printing requires lower inventory to get started.

- The technique minimizes waste production.

Cons

- The final print is not as durable as that achieved by flexographic and rotogravure printing.

- Pricing is fixed in digital printing, and bulk printing does not help reduce overall cost.

- It is not suitable for producing white colored prints.

Nanoimprint Lithography

Conventionally, lithography has been used for label printing. The process relies on the oil-based printing method, and the labels printed with lithography are then used for pasting on flexible films. Recent technological advancements in the lithography printing method have given rise to large area roll to roll nanoimprint lithography.

In this method, BOPP films are imprinted with high-quality holographic images when used at a definite temperature. Ideally, an optimum embossing temperature of around 110C, an embossing force of 6 kg/cm2, and a film speed of 32m/min have produced quality images. The method is still being considered for use on large-scale BOPP film printing.

Pros

- Produces high-quality holographic images

Cons

- It requires strict control of embossing temperature to avoid the thermal shrinkage of BOPP films.

Conclusion

Biaxially Oriented Polypropylene Films are the most common packaging films out there. They are used for packaging a host of different food and non-food products. As more and more brands are focusing on improving the visual outlook of products, the demand for high-quality prints on flexible films has also risen. Methods like flexographic and rotogravure printing have long been used to print on BOPP films, and flexography still remains the most widely used method. Finally, Digital printing and Nanoimprint lithography are relatively newer approaches that have not made their way into commercial scale printing.

For more bopp film manufacture packaginginformation, please contact us. We will provide professional answers.

Comments

Please Join Us to post.

0