What does SMT stand for?

Welcome to our blog, where we delve into the depths of technology to uncover its hidden gems. Today, we will uncover the meaning behind the coveted acronym "SMT" and explore its significance in various fields. So, let's embark on this enlightening journey together.

SMT stands for "Surface Mount Technology." This revolutionary technology has played a pivotal role in electronic manufacturing since its inception. Unlike traditional through-hole mounting processes, SMT offers compactness, cost-effectiveness, and enhanced electrical performance. By eliminating the need for drilling holes on circuit boards, SMT transformed the industry, allowing for higher component density and improved functionality.

Section 2: SMT in Electronics Manufacturing (150 words).

The advent of SMT has dramatically impacted the world of electronics manufacturing. By enabling precise, automated placement of components on circuit boards, SMT enhances manufacturing efficiency and reduces production costs. Heralding miniaturization, SMT has made it possible to create slimmer, more lightweight electronic devices without compromising performance. The reliable connections established by this technology ensure better longevity and durability of electronic products.

Section 3: SMT in the Automotive Industry (150 words).

SMT is not limited to consumer electronics alone; it has found a significant foothold in the automotive industry. By adopting SMT, automotive manufacturers can integrate increasingly sophisticated technologies into vehicles, such as advanced driver-assistance systems, infotainment systems, and electronic control units. SMT allows for seamless integration and efficient assembly, ensuring durability even in rugged vehicle environments.

Section 4: SMT in Aerospace and Defense (150 words).

Explore more:How Do I Choose a Packing Machine?

Universal Spline Hobbing Machine: Shaping Precision Gears

What are the Differences Between EVI and Traditional Heat Pumps?

Which is the Better Transportation Method: Cable Car or Ropeway?

How does a fixed grip chairlift work?

What are the parts of aerial work platform?

How to design an efficient lithium battery module assembly line?

The aerospace and defense sectors have also embraced SMT for its numerous advantages. With cutting-edge technologies at play in these industries, SMT provides a crucial solution for the dense packaging of components in mission-critical systems. The robustness of SMT technology offers reliable performance in extreme conditions, from the depths of the ocean to the vacuum of space.

Section 5: The Future of SMT (150 words).

As technology advances rapidly, the future of SMT looks promising. With the rise of the Internet of Things (IoT), wearable devices, and smart home systems, SMT will continue to evolve and adapt to meet the ever-growing demands of the connected world. The fusion of SMT with emerging technologies like artificial intelligence (AI) and robotics holds immense potential, enhancing precision, efficiency, and reliability in electronic manufacturing.

Conclusion: (50 words).

In conclusion, Surface Mount Technology (SMT) has revolutionized the electronics industry by offering myriad benefits in terms of compactness, cost-effectiveness, and longevity. We have explored its applications in various sectors, from automotive to aerospace, and discussed its bright future. SMT truly stands as a testament to human ingenuity and the relentless pursuit of technological advancements.

By providing the critical backbone for modern electronic devices, SMT empowers countless industries and drives innovation to new horizons.

Join us again as we continue unraveling the mysteries of technology and exploring the transformative impact it has on our lives.

Want more information on pcb handling conveyor, pcb loader, Pcb Buffering? Feel free to contact us.

Explore more:What size is a LN2 tank?

Demystifying the Cone Crusher Machine: Your Guide to Understanding its Function and Benefits

Advantages and Applications of CNC Gang Tool Lathes

What are the disadvantages of horizontal storage tanks?

AT&T Store: Unveiling the Best Tech Deals!

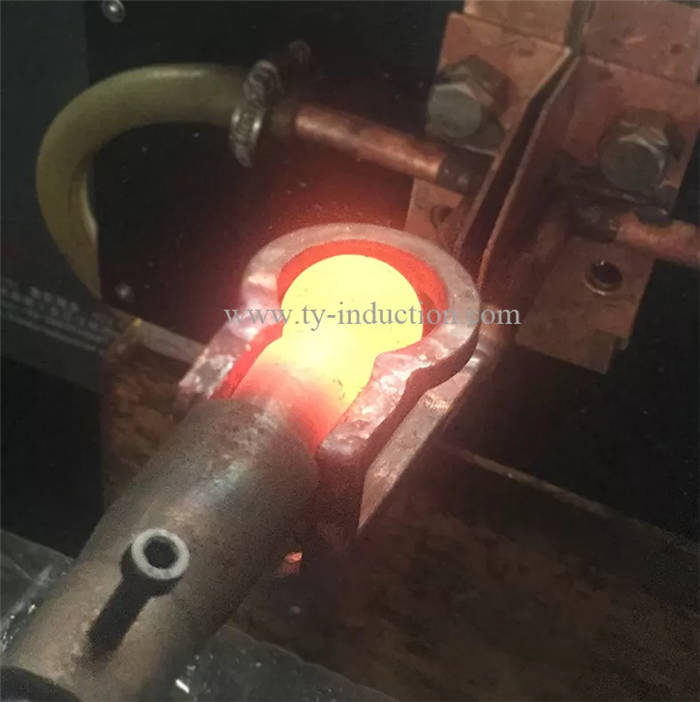

Revolutionizing Metal Hardening with Ultra-High Frequency Induction Heating Machines

The Future of Electronics Manufacturing: The Soldering Robot