Differences Between Hydrated Lime and Quicklime

Differences Between Hydrated Lime and Quicklime

Lime, a versatile and widely used material, plays a crucial role in various industries, from construction to agriculture. Two common forms of lime, hydrated lime and quicklime, are fundamental components with distinct properties and applications. Let's delve into the differences between hydrated lime and quicklime to understand their unique characteristics and uses.

1. Chemical Composition:

a. Quicklime (Calcium Oxide):

Quicklime, also known as calcium oxide (CaO), is the result of heating limestone or dolomite to extreme temperatures, a process known as calcination. This intense heat causes the limestone to undergo a chemical transformation, releasing carbon dioxide and leaving behind calcium oxide.

b. Hydrated Lime (Calcium Hydroxide):

Hydrated lime is the product of adding water to quicklime, a process known as slaking or hydration. This chemical reaction results in the conversion of calcium oxide into calcium hydroxide (Ca(OH)₂). The addition of water is a controlled process to ensure proper hydration without excessive heat generation.

2. Physical Form:

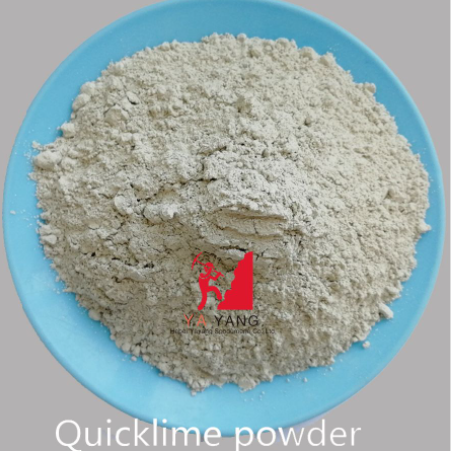

a. Quicklime:

Quicklime is typically available in the form of large, irregular chunks or granules. Its appearance can range from white to a light gray, depending on impurities present in the original limestone.

b. Hydrated Lime:

Hydrated lime is a fine powder, resulting from the hydration process. It has a smoother texture and is more easily handled than quicklime. The powder can vary in color, commonly appearing white or off-white.

3. Reactivity:

a. Quicklime:

Quicklime is highly reactive and exothermic. When water is added, it undergoes a vigorous exothermic reaction, releasing heat. This property makes quicklime suitable for various applications where its reactivity is advantageous.

b. Hydrated Lime:

Hydrated lime, being the product of slaking quicklime, is less reactive than its precursor. The hydration process is controlled to avoid excessive heat generation. It still exhibits reactivity but to a lesser extent compared to quicklime.

4. Applications:

a. Quicklime:

Quicklime finds applications in diverse industries, including:

Steel Industry: Used to remove impurities from molten metals.

Water Treatment: Aids in the purification of water and wastewater.

Soil Stabilization: Enhances the properties of soils in construction.

Chemical Manufacturing: Serves as a precursor in various chemical processes.

b. Hydrated Lime:

Hydrated lime is used in applications such as:

Construction: As a mortar additive or soil stabilizer.

Environmental Remediation: Neutralizing acidic waste streams.

Water Treatment: Adjusting pH levels and softening water.

Food Industry: As a pH regulator and firming agent in certain food products.

5. Handling and Safety:

a. Quicklime:

Due to its high reactivity, handling quicklime requires caution. Direct contact with skin or eyes can lead to burns, and inhalation of dust should be avoided.

b. Hydrated Lime:

Hydrated lime is generally safer to handle, as its reactivity is lower than that of quicklime. However, standard safety precautions, such as wearing protective gear, are still recommended.

6. Storage:

a. Quicklime:

Quicklime should be stored in a dry environment to prevent unintended hydration. Moisture can lead to the formation of hydrated lime.

b. Hydrated Lime:

Hydrated lime is less prone to unintended reactions with moisture. However, it is still advisable to store it in a dry location to maintain its powder form.

Conclusion:

In the realm of lime, understanding the differences between hydrated lime and quicklime is crucial for selecting the appropriate material for specific applications. Whether it's the controlled reactivity of hydrated lime or the vigorous capabilities of quicklime, these lime variants continue to play pivotal roles in shaping various industries and applications worldwide.