GPPS Plastic Material: Unlocking the Potential of Versatile Thermoplastic

Introduction

Welcome to our comprehensive guide on GPPS (General Purpose Polystyrene) Plastic Material! In this article, we delve into the intricacies of GPPS, exploring its properties, applications, manufacturing processes, and environmental impact. As industry experts, we aim to provide you with an informative and authoritative resource to outrank other websites on Google and become your go-to destination for all things related to GPPS plastic.

What is GPPS Plastic?

GPPS, or General Purpose Polystyrene, is a widely used and versatile thermoplastic. It belongs to the polystyrene family, known for its transparency, rigidity, and excellent electrical properties. GPPS is a linear polymer made from styrene monomers through polymerization.

Properties of GPPS Plastic

1. Transparency: GPPS boasts exceptional transparency, making it a popular choice for applications that require optical clarity. This feature makes it suitable for products like CD cases, optical lenses, and display panels.

2. Rigidity: With a high stiffness level, GPPS is well-suited for applications where structural integrity is crucial. It offers dimensional stability and maintains its shape under various conditions.

3. Electrical Insulation: GPPS exhibits excellent electrical insulation properties, making it ideal for electronic components, household appliances, and electrical enclosures.

4. Processability: The ease of processing GPPS through injection molding, extrusion, and thermoforming makes it a cost-effective material for various manufacturing processes.

5. Water Resistance: GPPS has good resistance to moisture, making it suitable for applications where exposure to water or humidity is a concern.

Applications of GPPS Plastic

GPPS is extensively used across diverse industries due to its unique properties. Some prominent applications include:

1. Packaging Industry

GPPS is widely utilized in the packaging industry for producing containers, cups, trays, and cutlery. Its clarity and affordability make it an excellent choice for displaying food and beverages.

2. Electronics and Appliances

As a reliable electrical insulator, GPPS is commonly employed in the manufacturing of electronic components, including computer housings, TV cabinets, and household appliances.

3. Medical Devices

In the medical field, GPPS finds its way into various medical devices like test tubes, petri dishes, and syringes, where transparency and sterile properties are essential.

4. Stationery and Office Supplies

GPPS is used in making a variety of stationery items such as pen bodies, rulers, and transparent folders.

5. Automotive Industry

GPPS is utilized in the automotive industry for creating taillights, interior trim, and indicator lenses, thanks to its optical clarity and ease of molding.

Manufacturing Process

The production of GPPS plastic typically involves two main processes:

1. Polymerization

The first step is the polymerization of styrene monomers, usually through a free-radical mechanism. This process yields a clear, amorphous polymer with excellent transparency.

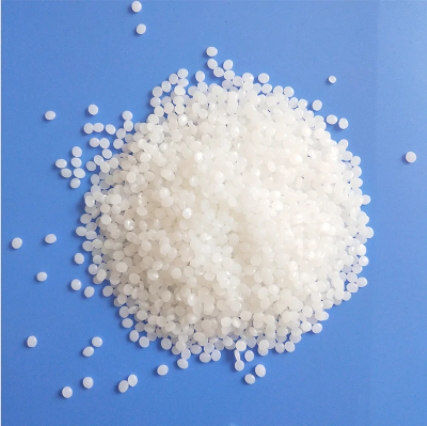

2. Pelletization

After polymerization, the resultant polystyrene is cooled, solidified, and cut into small pellets for further processing. These pellets can then be used in various manufacturing methods, such as injection molding or extrusion.

Environmental Impact and Sustainability

As part of our commitment to sustainable practices, we acknowledge the importance of addressing the environmental impact of plastics. While GPPS itself is recyclable, its recycling rate is not as high as desired due to various factors like contamination and sorting challenges. As an alternative, biodegradable and compostable plastics are being explored to reduce the environmental burden of traditional plastics.

Conclusion

In conclusion, GPPS (General Purpose Polystyrene) Plastic Material is a versatile thermoplastic with remarkable properties that cater to a wide range of applications across industries. Its transparency, rigidity, and electrical insulation properties make it an excellent choice for numerous products. We hope this comprehensive guide has provided valuable insights into the world of GPPS and its significance in modern manufacturing.