How Does Stainless Steel Gate Valve Work?

Stainless steel gate valves are essential components in industries that require precise control of fluids such as water, oil, and gas. Understanding how these valves work can help optimize their performance and ensure the efficient operation of machinery and systems. In this article, we will delve into the inner workings of stainless steel gate valves and explore the mechanism behind their function.

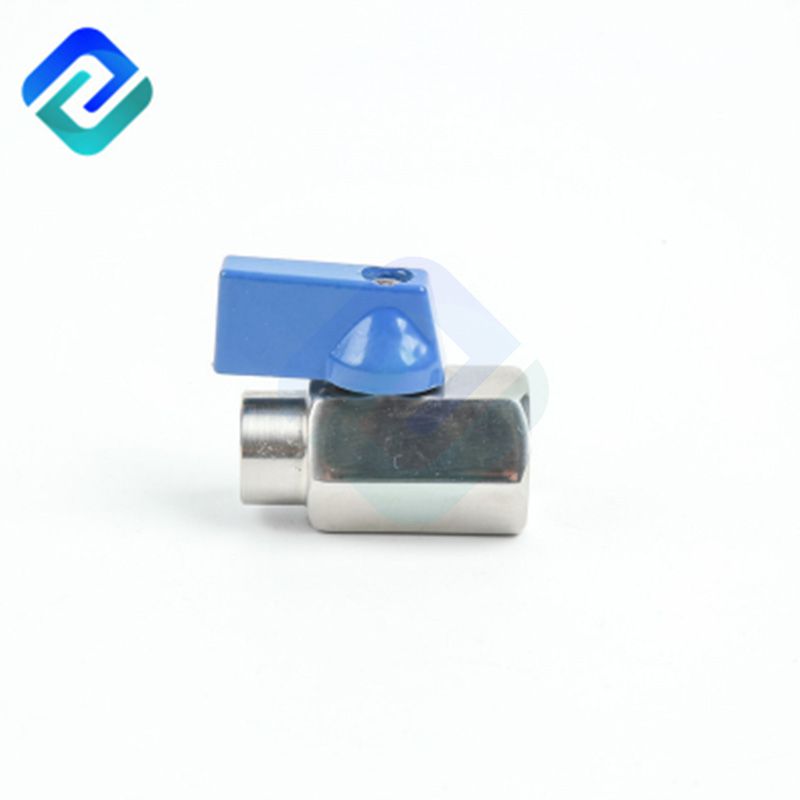

Stainless steel gate valves are commonly used in applications where a straight-line flow of fluid and minimal restriction is required. They consist of a gate or wedge that slides up and down to control the flow of fluid through the valve. The gate is usually made of stainless steel, which provides durability and corrosion resistance.

**2. How Stainless Steel Gate Valves Work**.

1. Opening the Valve: When the valve is open, the gate is lifted to allow the fluid to flow through the valve unobstructed. This creates a straight-line flow path, minimizing pressure drop and turbulence in the fluid.

2. Closing the Valve: To close the valve, the gate is lowered to block the flow of fluid. The tight seal created by the gate prevents any leakage or loss of pressure in the system. This makes stainless steel gate valves ideal for applications where isolation and reliable shut-off are crucial.

3. Types of Gate Valves: There are two main types of gate valves - rising stem and non-rising stem. In a rising stem gate valve, the stem moves up and down as the gate is opened and closed. This provides a visual indication of the valve's position. In a non-rising stem gate valve, the stem remains in a fixed position while the gate moves up and down.

**3. Advantages of Stainless Steel Gate Valves**.

1. Corrosion Resistance: Stainless steel gate valves are highly resistant to corrosion, making them suitable for a wide range of industries, including chemical processing, water treatment, and oil and gas.

2. Durability: Stainless steel is a durable material that can withstand high temperatures, pressures, and harsh environments. This makes stainless steel gate valves long-lasting and reliable in demanding applications.

Explore more:The Benefits of Using Petroleum Chlorine Globe Valve for Sale

10 Questions You Should Know about Control Pressure Valve

Everything You Need To Know To Find The Best Smt Nozzle Manufacturer

Weir Type Diaphragm Valve: A Reliable Solution for Flow Control

Plug Valves: Versatile Flow Control Solutions

High-Pressure Quick Connect Nozzle Spray Gun: The Ultimate Tool for Efficient Cleaning

The Advantages of Overhead Conveyor Bearings in Industrial Automation

3. Easy Maintenance: Stainless steel gate valves are relatively easy to maintain and service. The simple design of the valve makes it easy to disassemble and clean, reducing downtime and maintenance costs.

**4. Applications of Stainless Steel Gate Valves**.

Stainless steel gate valves are used in various industries and applications, including:

1. Water Treatment: Stainless steel gate valves are commonly used in water treatment plants to control the flow of water through pipelines and systems.

2. Oil and Gas: In the oil and gas industry, stainless steel gate valves are used to regulate the flow of oil, gas, and other fluids in pipelines and production facilities.

3. Chemical Processing: Stainless steel gate valves are essential in chemical processing plants for controlling the flow of chemicals and raw materials in manufacturing processes.

**5. Conclusion**.

In conclusion, stainless steel gate valves play a crucial role in controlling the flow of fluids in industrial applications. Their robust construction, corrosion resistance, and reliability make them ideal for a wide range of industries. By understanding how stainless steel gate valves work and their advantages, businesses can ensure the efficient operation of their machinery and systems.

For more information, please visit DN125 Ductile Iron Ball Check Valve, Non Slam Check Valve Reduced Price Deals, DN250 Ductile Iron Ball Check Valve Manufacturer.

Explore more:Choosing the Right Activated Carbon Filter for Your Needs

Drum Gear Coupling: The Backbone of Efficient Power Transmission

Mud Desander: Enhancing Drilling Fluid Management in Oil and Gas Operations

Centrifugal Pumps: Harnessing the Power of Fluid Dynamics

What is a waste heat recovery boiler and how does it work?

Steel Braided Hydraulic Hose: The Strong and Reliable Solution

Factors to Consider Before Choosing an Overhead Block Clamp