The Benefits of Using Taper Taps: A Complete Guide

When it comes to choosing the right tools for your machining projects, there are a lot of options out there. One tool that often gets overlooked but can be incredibly beneficial is the taper tap. Taper taps are designed to cut threads in materials like metal and plastic, and they offer a number of advantages over other types of taps.

In this complete guide, we will explore the benefits of using taper tapstaper taps and why they should be a staple in any machinist’s toolbox.

What is a Taper Tap?

Before we dive into the benefits of using taper taps, let's first clarify what they are. A taper tap is a type of tap that has a gradual taper along its length, starting from a small diameter at the tip and increasing in size toward the shank. This taper allows the tap to gradually cut threads in a hole, making it easier to start and less likely to bind or break than a tap with a straight or bottoming design.

Now that you understand what a taper tap is, let's explore some of the benefits of using this versatile tool.

1. Easier Starting.

One of the biggest advantages of using a taper tap is that it makes starting a new thread much easier. The gradual taper allows the tap to align itself more easily with the hole, reducing the risk of the tap wandering off course or cutting crooked threads. This can save you time and frustration when starting a new thread in a piece of material.

2. Reduced Risk of Breaking.

Another benefit of using taper taps is that they are less likely to break or bind than other types of taps. The gradual taper allows the tap to cut more smoothly through the material, reducing the risk of the tap getting stuck or snapping off. This can save you money on replacement taps and downtime on your projects.

3. Versatility.

Taper taps are also incredibly versatile and can be used on a wide range of materials, including metals like steel, aluminum, and brass, as well as plastics. This makes taper taps a great choice for a variety of machining projects, whether you are working on automotive parts, household appliances, or DIY projects.

Explore more:Revolutionizing Energy Production: Is the Right Angle Bellows Seal Globe Valve the Key to Sustainable Power Generation?

10 Questions You Should Know about Non Slam Check Valve Lowest Price Offers

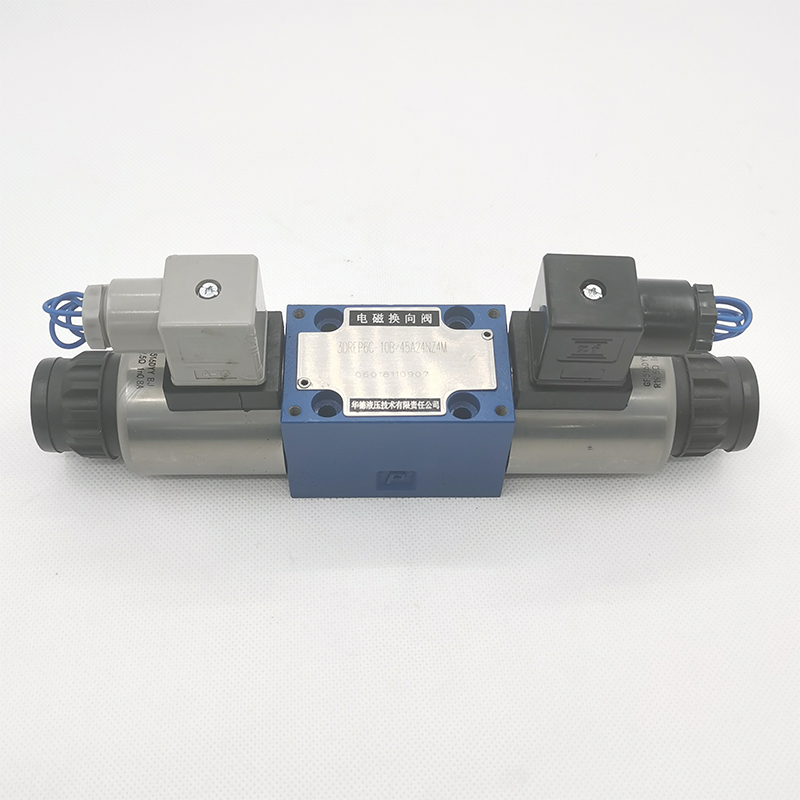

What is hydraulic directional control valve?

Natural Gas Y Strainer: Ensuring Optimal Gas Flow and Efficiency

What is API 6D ball valve?

Hydraulic Rubber Seal: Ensuring Efficiency and Reliability in Hydraulic Systems

Factors to Consider When Choosing a Filter Press Feed Pump

4. Improved Thread Quality.

Because taper taps cut threads gradually, they can produce cleaner and more precise threads than other types of taps. This can be especially important in applications where thread quality is critical, such as in aerospace or medical devices. Using a taper tap can help ensure that your threads are strong and secure, reducing the risk of failure down the line.

5. Cost-Effective.

While taper taps may cost slightly more than other types of taps, their durability and versatility can make them a cost-effective choice in the long run. By investing in high-quality taper taps, you can reduce the risk of tap breakage and achieve better results on your projects, saving you time and money in the process.

6. Improved Tool Life.

Taper taps are designed to last a long time, thanks to their gradual cutting action and durable materials. By using taper taps regularly and taking care of them properly, you can extend the life of your taps and get more use out of them before they need to be replaced. This can lead to significant cost savings over time and help you get the most out of your machining tools.

7. Easy Maintenance.

Another benefit of using taper taps is that they are relatively easy to maintain. With regular cleaning and sharpening, you can keep your taper taps in top condition and ensure that they are always ready to use when you need them. This can help you avoid downtime on your projects and keep your machining operations running smoothly.

In conclusion, taper taps are a versatile and cost-effective tool that can provide a number of benefits for machinists and DIY enthusiasts alike. From easier starting and reduced risk of breaking to improved thread quality and longer tool life, taper taps offer a range of advantages that make them a valuable addition to any toolbox. Consider investing in high-quality taper taps for your next project and experience the benefits for yourself.

Want more information on aax manual tongs, api 6a expanding gate valves? Feel free to contact us.

Explore more:What is the difference between rigid and flexible flange coupling?

What is the difference between a slurry pump and a water pump?

Unveiling the Versatility and Importance of O-Rings

Are Kubota diesel engines good?

How Does a Vertical Slurry Pump Work?

Enhancing Oilfield Safety with Sucker Rod Blowout Preventers (BOPs) for High-Pressure Environments

Unraveling the Features of Triplex Mud Pumps