Where is Drill Pipe Manufactured?

Introduction

The drilling industry is an essential component of various sectors, from oil and gas exploration to mining and geothermal energy production. At the heart of drilling operations lies the drill pipe, a critical piece of equipment that enables the extraction of valuable resources from beneath the Earth's surface. In this article, we will delve into the fascinating world of drill pipe manufacturing, exploring the locations where drill pipes are produced and the factors that influence their production.

Where is Drill Pipe Manufactured?

The Global Landscape of Drill Pipe Manufacturing

Drill pipe manufacturing is a global industry with production facilities located in several countries around the world. The choice of location for manufacturing drill pipes depends on a combination of factors, including proximity to drilling operations, access to raw materials, labor costs, and technological capabilities. Let's take a closer look at some of the key regions and countries where drill pipes are manufactured:

United States: The United States has a long history of oil and gas exploration, making it one of the largest consumers of drill pipe. Consequently, there are numerous drill pipe manufacturing facilities located in states with active drilling operations, such as Texas, Oklahoma, and Louisiana. American-made drill pipes are highly regarded for their quality and are often used in domestic and international drilling projects.

China: China has emerged as a significant player in the global drill pipe manufacturing industry. The country's abundant labor force and access to raw materials have contributed to its competitive advantage in this sector. Chinese drill pipe manufacturers cater to both domestic and international markets, offering a range of products that meet industry standards.

Europe: Several European countries, including Germany, the United Kingdom, and Norway, have drill pipe manufacturing facilities. Europe's emphasis on quality and technology has led to the production of high-quality drill pipes that are in demand worldwide. These manufacturers often serve the North Sea drilling operations and export their products to other regions.

Russia: Russia, as a major player in the oil and gas industry, also has a significant presence in drill pipe manufacturing. Russian drill pipe manufacturers provide products for both domestic and international drilling projects, particularly in the oil-rich regions of the Caspian Sea and Siberia.

Canada: Canada, known for its vast natural resources, has a growing drill pipe manufacturing industry. Canadian drill pipe manufacturers cater to the needs of the country's mining, oil, and gas sectors, as well as exporting their products to global markets.

Middle East: Some countries in the Middle East, such as the United Arab Emirates, have invested in drill pipe manufacturing facilities to support their oil and gas exploration activities. These facilities often produce drill pipes that meet the stringent requirements of the region's drilling operations.

Factors Influencing Location

Several factors influence the choice of location for drill pipe manufacturing facilities:

Proximity to Drilling Operations: Manufacturers often establish facilities close to drilling operations to reduce transportation costs and provide quick access to customers. This is especially relevant in regions with active drilling activities.

Access to Raw Materials: Availability of raw materials, particularly steel, is a crucial factor. Proximity to steel mills or reliable suppliers ensures a steady supply of materials required for drill pipe production.

Labor Costs: Labor costs can significantly impact manufacturing expenses. Countries with a skilled and cost-effective labor force are attractive locations for drill pipe manufacturing.

Technological Capabilities: Advanced manufacturing technologies and processes are essential for producing high-quality drill pipes. Manufacturers often choose locations with access to cutting-edge technology and skilled engineers.

Market Demand: The demand for drill pipes in a specific region or market segment can influence the location of manufacturing facilities. Manufacturers may establish plants in regions with high demand to meet local needs.

Regulatory Environment: Regulatory factors, including environmental regulations and trade policies, can affect the feasibility of manufacturing operations in a particular location.

Quality Standards in Drill Pipe Manufacturing

Regardless of the location, drill pipe manufacturers adhere to stringent quality standards to ensure the safety and effectiveness of their products. These standards encompass various aspects of drill pipe production, including:

Material Selection: Manufacturers carefully choose the type of steel and alloy compositions that meet industry standards and the specific requirements of drilling operations.

Heat Treatment: Heat treatment processes, such as quenching and tempering, are employed to enhance the mechanical properties of the drill pipe, including its strength and resistance to wear.

Inspection and Testing: Drill pipes undergo rigorous inspection and testing procedures, including non-destructive testing (NDT) methods, to identify defects and ensure their integrity.

Thread Machining: The threading process is critical, as it ensures the proper connection between drill pipes. Precise machining and quality control are essential to prevent thread failures.

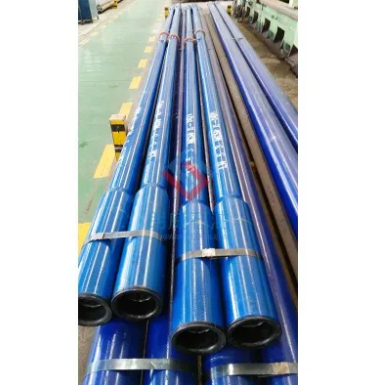

Coating and Protection: Manufacturers often apply coatings to protect the drill pipes from corrosion and wear, extending their operational life.

Certification: Drill pipes are typically certified to international standards such as API (American Petroleum Institute) and ISO (International Organization for Standardization) to guarantee their quality and reliability.

Conclusion

Drill pipe manufacturing is a global industry with production facilities distributed across various regions and countries. The choice of location is influenced by factors such as proximity to drilling operations, access to raw materials, labor costs, technological capabilities, and market demand. Regardless of where they are manufactured, drill pipes must meet stringent quality standards to ensure their safety and effectiveness in drilling operations. As the demand for natural resources continues to grow, the drill pipe manufacturing industry will play a vital role in supporting the global exploration and extraction of valuable minerals, oil, and gas.