10 Things to Consider When Buying 304 Stainless Steel Cable Ties

304 vs. 316 Stainless Steel Cable Ties

Zhonggu supply professional and honest service.

When it comes to selecting stainless steel for any application, the choice often comes down to 304 vs. 316. Both are part of the austenitic family of stainless steels, which are popular for their corrosion resistance and durability. However, understanding the nuances between these two types of stainless steel is crucial for making an informed decision, especially when choosing stainless steel cable ties for specific applications.

General Comparison Between 304 and 316 Stainless Steel

304 Stainless Steel is the most commonly used type of stainless steel around the globe. It's an austenitic steel known for its balance of ease of forming and durability. It contains 18% chromium and 8% nickel, providing excellent resistance to a wide range of atmospheric, chemical, and food industry exposures. (If you are familiar with the term 18/8 stainless steel pots or flatware this is what it means)

316 Stainless Steel adds 2% molybdenum to the mix, enhancing its corrosion resistance, particularly against chlorides like sea salt and pool chemicals. This makes 316 stainless steel the preferred choice in marine environments, chemical processing equipment, and other high-corrosion areas.

Stainless Steel Cable Ties: 304 vs. 316

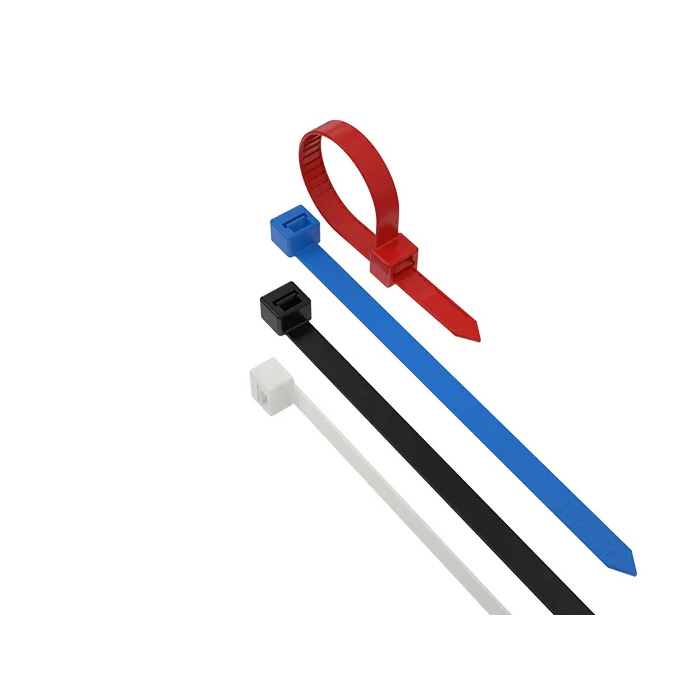

Cable ties or, as they are often referred to, zip ties are very popular for their versatility across various applications, and stainless steel zip ties excel where durability and environmental resistance are crucial. 304 stainless steel cable ties are suited for most applications, providing a durable method for bundling and securing while 316 stainless steel cable ties offer superior corrosion resistance, ideal for harsher environments.

Differences in Application

- 304 Stainless Steel Cable Ties are suitable for most general applications, including indoor and outdoor settings where significant exposure to harsh chemicals or saltwater isn't a concern. They offer a strong, durable method for bundling and securing cables, hoses, and other items in automotive, construction, and industrial applications. Like zip ties, 304 stainless steel braided sleeving is mainly used for abrasive and corrosive environments.

316 Stainless Steel Cable Ties

shine in environments where additional corrosion resistance is needed. Their superior durability against chlorides makes them ideal for marine, chemical processing, and outdoor applications in coastal areas. These ties are crucial for securing equipment in harsh environments where failure due to corrosion could have serious implications.

Where It Makes a Difference

The choice between 304 and 316 stainless steel cable ties largely depends on the environmental conditions they will be exposed to. For environments with high exposure to salt, chlorine, or other harsh chemicals, 316 stainless steel cable ties are essential for long-term reliability and safety. Conversely, in less aggressive environments, 304 stainless steel cable ties provide a cost-effective, durable solution.

Example of Use:

- Marine Applications

: 316 is preferred for its enhanced corrosion resistance to salt and chlorides.

Explore more:

Benefits of Using Sublimation Paper

What are the types of cell culture consumables?

Are biodegradable plastic bags eco-friendly?

The Types of Self-Adhesive Graphic Film

What Sausage Casings Are Made of?

What are Benefits of PET Protective Film?

What are the packaging materials for tea?Are you interested in learning more about Releasable Zip Ties? Contact us today to secure an expert consultation!

- Industrial and Construction

: For typical industrial environments without extreme exposure to corrosive chemicals, 304 provides a balance of strength and corrosion resistance.

- Automotive

: 304 is often sufficient for securing cables under the hood, where direct exposure to salt and harsh chemicals is minimal.

- Chemical Processing Plants

: 316 is necessary for its resistance to a wide range of chemicals and solvents.

Metal Cable Ties Beyond Stainless Steel

Aside from stainless steel cable ties, other metal options like colored chrome, metal detectable, and metal barb ties cater to specific needs. Colored chrome ties aid in identification and organization, while metal detectable ties are essential in preventing contamination in sensitive manufacturing processes. Metal barb ties, known for their secure locking mechanism, are ideal for applications requiring a strong, tamper-proof solution. Each type serves unique industries and applications, highlighting the importance of selecting the right cable tie based on environmental conditions and specific requirements.

Conclusion

The decision between 304 and 316 stainless steel cable ties should be guided by the specific conditions and requirements of the application. Understanding the differences between these two types of stainless steel allows for an informed choice, ensuring the longevity and reliability of cable ties in any given environment. Whether securing cables in a marine setting or organizing wires in an industrial plant, selecting the right grade of stainless steel cable tie is paramount to achieving optimal performance and durability.

Commonly Asked:

Q: Can metal cable ties be reused?

A: While metal cable ties are designed for single-use due to their locking mechanisms, metal barb ties and certain stainless steel zip ties with releasable features can be adjusted or reused in some applications. However, for most metal zip ties, especially those used in critical or permanent installations, reusing is not recommended to ensure maximum security and reliability.

The Uses and Buying Considerations of Stainless Steel Cable ...

Product reliability. You can use internet technology and other methods to check the registered trademarks displayed by the shop that offers preferentially priced stainless steel cable ties, rather than knowing their quality. The production and manufacturing conditions of stainless steel cable tie factory, and original website addresses are really clear? In addition, all technically professional products will display the original quality inspection report.

Sample quality. During the testing phase of stainless steel cable ties, we cannot believe the store's samples arbitrarily. We should not only look at the main parameters of the sample data information. We can compare several products and put samples of different brands together for comparison. This way, we can easily see whether the quality of the product is good or bad. In addition to checking the quality of the sample, it is recommended that customers supervise the entire process of delivery as much as possible and request sample inspections. After delivery, the store can test again.

Well-known brands with user evaluations and work experience. Each product is formed by many professional abilities. When choosing, customers will choose high-quality stainless steel cable ties. The secret of the brand is one of the important reasons to attract customers to buy. The product must have high quality in terms of actual effects and safety factors. In addition, when making choices and purchases, we must also pay attention to integrating the reputation of well-known brands and make choices according to customer feedback. Above are several aspects that we should pay attention to when purchasing stainless steel cable ties. Paying attention to these matters can ensure the quality of the product and make everyone better use the product.

Stainless steel cable ties products are not limited by the shape and size of the object being tied. The simple fastening structure simplifies the complexity of traditional clamps, and good fastening performance ensures the safety of the object being tied. Stainless steel cable ties are made of corrosion-resistant and high-temperature-resistant materials, ensuring the beauty of the environment and fire protection requirements.

What is co-extruded film in food packaging?

The Benefits of Printed Shrink Film

The Difference Between Natural Casing and Artificial Casing

What is anti-static film?

How do you know if a plastic bucket is food grade?

What Is A Dropper Bottle Called?

What Makes Perfume Bottles So Captivating?