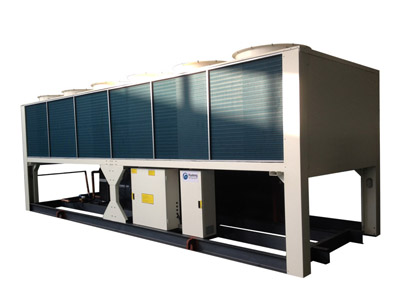

Air-Cooled Chiller vs. Water-Cooled Chiller Comparison

Industrial processes generate large amounts of heat, which must be dissipated to avoid damage to sensitive equipment and to protect finished products. Proven methods of monitoring and regulating temperatures at optimum levels involve the use of a cooling system, which can be either water or air cooled. This article will focus on the differences between water cooled chillers and air cooled chiller systems.

Air-cooled chillers vs. water-cooled chillers

Although both air-cooled and water-cooled chillers function to remove unwanted heat from the manufacturing process, they differ in different ways. Deciding which chiller type is best for your industrial process depends on several factors, including

Chiller condenser mechanism

Environmental and location considerations

Air-cooled versus water-cooled condensers

There is a distinct difference between air-cooled and water-cooled chillers with condensers. Air-cooled chillers are equipped with condensers that use ambient air to lower the temperature of the refrigerant. Fans are used to force the air through the ducts containing the refrigerant, thus removing the heat from it. The cooling refrigerant used in the chiller can then be circulated through the industrial process to achieve the cooling effect.

Water Cooled Screw Chiller

In contrast, water-cooled chillers use the high heat capacity of water to promote refrigerant cooling. The typical coolant used in a water cooled system is a mixture of water and glycol circulating in a sealed network of pipes. Cooling occurs when the cooled refrigerant passes through a heat exchanger that interfaces with the industrial process at hand. The heated coolant is then returned to the cooling tower or refrigeration unit to remove the heat gained in preparation for another cooling cycle.

Environmental / location considerations

The planned location of the chiller plant is another important factor to consider when deciding on an industrial chiller. Depending on the site plan, there are advantages and disadvantages to choosing either an air-cooled or water-cooled chiller.

Indoor locations

Both air-cooled and water-cooled chillers can be installed in an indoor location. However, additional space considerations must be made for air-cooled chillers. This is because air-cooled chillers need access to sufficient ambient air in order to operate properly.

Explore more:

How to Make Paper Briquettes for Eco-Friendly Fuel

Ultimate Guide to Choosing the Right Pallet Strap Machine

10 Questions You Should Know about Electric Powered Mobile Welding Equipment Solutions

10 Questions You Should Know about Safety for Construction Sites

Key Questions to Ask When Ordering How Are Vegan Meat Alternatives Produced?

The Advantages of Employing a Cardboard Banding Machine

Who produces the most gypsum?

Placing an air-cooled chiller in a poorly ventilated indoor space will hinder its cooling capacity and reduce its efficiency. In contrast, chillers can be installed in areas with minimal ventilation, as their cooling towers can be placed on the exterior of the building.

Outdoor locations

The choice of air-cooled chillers is advantageous in outdoor environments because of the unrestricted access to the high flow of ambient air required to promote coolant cooling. Water cooled chillers are rarely installed outdoors.

Air Cooled Screw Chiller

Environments with elevated temperatures

Water cooled chillers are the best choice for installation in industrial areas with high heat output. Air cooled units do not perform well in areas with elevated temperatures as chillers and cooling towers will struggle to dissipate the heat within the coolant pipework.

Areas with poor water supply

The choice is easy in situations where the water supply is inadequate. In this case, an air-cooled chiller is the best choice, provided it is installed in a well-ventilated area. The available water can therefore be directed to other essential production processes.

Environmental regulations

Local or regional regulations regarding industrial waste water are a key issue to be addressed when selecting a chiller system. In this respect, air-cooled chillers are more beneficial as there is no need to worry about waste being released into the environment.

The link between air-cooled and water-cooled chillers Cold Shot Chillers

At Huazhao Refrigeration Equipment, we offer a wide range of air-cooled and water-cooled industrial chillers designed to meet all your industrial and commercial process cooling needs. To find out more about how we can help meet your specific process cooling needs, contact us online today!

Key Considerations to Keep in Mind When Purchasing High Efficiency Solar Panels

The Advantages of Investing in a 550 kW Industrial Generator

The Advantages of Implementing 250KW Cotton Straw Briquetting Machines

How to Choose a Small Box Strapping Machine?

How to Choose a Mute Screw Air Compressor?

4 Tips to Select the Right Types of Paint

The Advantages of Investing in a Smart Thermostat