Guide to Extrusion Profile Heat Sinks

Extruded metal heat sinks are among the lowest cost, widest used heat spreaders in electronics thermal management. Besides their affordability, extruded heat sinks are lightweight, readily cut to size and shape, and capable of high levels of cooling.

Metal Choices

Most extruded heat sinks are made from aluminum alloys, mainly from the 6000 alloy series, where aluminum dominates. Trace amounts of other elements are added, including magnesium and silicon. These alloys are easy to extrude and machine, are weldable, and can be hardened.

Common alloys for extruded heat sinks are the 6063 metals. These can be extruded as complex shapes, with very smooth surfaces. 6061 aluminum is also used for extrusions. Its tensile strength (up to 240 MPa) is superior to 6063 alloys (up to 186 MPa). In addition to heat sinks, these aluminum alloys are popular for architectural applications such as window and door frames.

Figure 1. An extruded aluminum heat sink with a black anodized finish.

The surfaces of these metals can be anodized to replace their naturally occurring surface layer of aluminum oxide. Anodizing provides more heat transfer, corrosion resistance and better adhesion for paint primers. It is an electrochemical process that increases surface emissivity, corrosion and wear resistance, and electrical isolation.

The Extruding Process

Aluminum alloys are popular for extruding as heat sinks because they provide both malleability and formability. They can be easily machined and are as little as one-third the density of steel. This results in extrusions that are both strong and stable, at a reduced cost relative to other materials.

Explore more:What is considered low volume production?

Why piston engines are better than rotary?

How Do You Determine Wire Mesh Size?

What are the disadvantages of iron stairs?

What is the principle of cartridge filter?

Kelly Valve vs. Competing Solutions in Fluid Control

Modernize Your Space with Sleek Metal Partitions

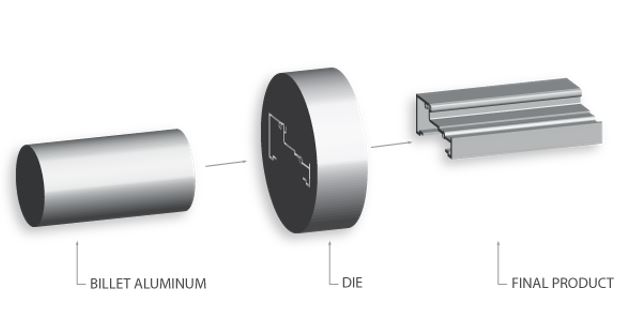

Figure 2. Heated aluminum alloy billets are pushed through a die to produce extruded length heat sinks and other parts.

The aluminum extrusion process starts with designing and creating the die that will shape the heat sink profile. Once this has been done, a cylindrical billet of aluminum is heated up in a forge to high temperatures, generally between 800-925°F (427-496°C). Next, a lubricant is added to the aluminum to prevent it from sticking to any of the machinery. It is then placed on a loader and pressure is applied with a ram to push heated aluminum through the die.

During this process, nitrogen is added in order to prevent oxidation. The extruded part will pass completely through the die and out the other side. It has now been elongated in the shape of the die opening. The finished extrusion is then cooled, and if necessary, a process of straightening and hardening creates the finished product.

They can be cut to the desired lengths, drilled and machined, and undergo a final aging process before being ready for market.

Finished heat sinks typically come with anodized surfaces, which can enhance their thermal performance. Alternatively, a chromate finish provides some corrosion protection, or can be used as a primer before a final paint or powder coating is applied.

Shapes of Extruded Heat Sinks

Extruded heat sink profiles range from simple flat back fin structures to complex geometries for optimized cooling. They can be used for natural (passive) or forced convection (active) with an added fan or blower. Extruded profiles can also include special geometries and groove patterns for use with clip or push pin attachment systems.

Extrusions are also available in bulk lengths, e.g. 8 feet, which can be cut to different lengths per customer needs.

Which stator and rotor combination offers superior performance?

Which Milling Collet Types offer the best precision for the purchase stage?

Exploring Milling Collet Types: A Comprehensive Guide

Does Upack have discounts?

Wrought vs Forged Fittings: Which Reigns Supreme in Plumbing? Get the Ultimate Comparison!

Uncovering the Ultimate Index of Chuck Norris: All You Need to Know!

The Ultimate Guide to the Chuck Index