How do you install corrugated HDPE pipe?

If you're looking to install corrugated HDPE pipe for a project, you've come to the right place! In this article, we'll walk you through the steps on how to properly install corrugated HDPE pipe. .

1. Preparing the Site .

Before you begin the installation process, it's important to properly prepare the site where the pipe will be laid. Make sure the area is free of any debris or obstructions that could interfere with the installation process. It's also a good idea to contact your local utility companies to ensure there are no underground cables or pipes in the area.

2. Choosing the Right Pipe .

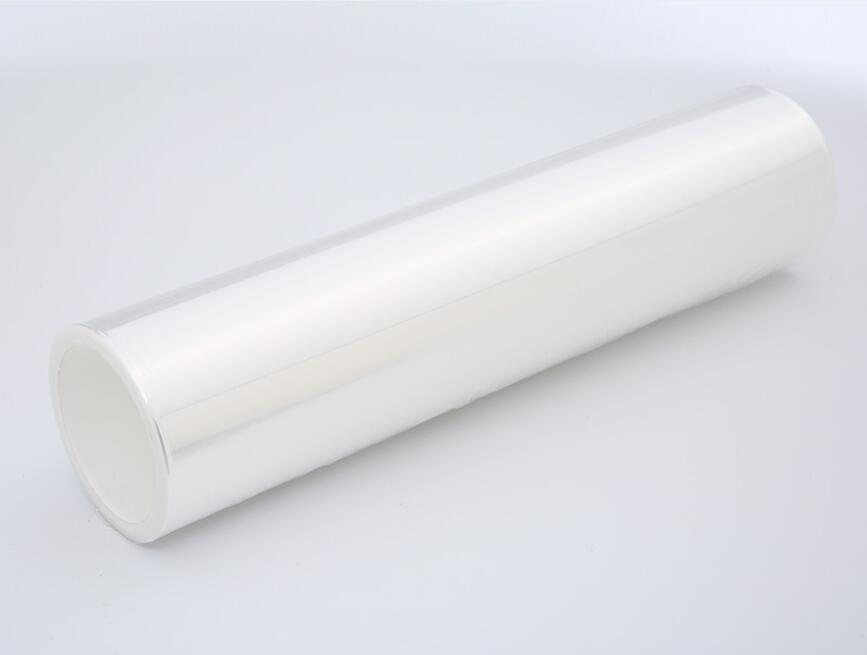

When selecting corrugated HDPE pipe, it's important to consider the diameter and length that will best suit your project needs. Make sure to also choose a reputable supplier who can provide you with high-quality pipe that meets industry standards.

3. Excavation .

Next, you'll need to excavate the trench where the pipe will be installed. The trench should be wide enough to accommodate the pipe and should have a uniform slope to allow for proper drainage. It's crucial to make sure the bottom of the trench is firm and level to provide a stable foundation for the pipe.

4. Connecting the Pipe .

Explore more:The Differences Between PVC and RPET Material

PCR Recycling: A Sustainable Solution for a Greener Future

Advantages and Disadvantages of Injection Moulding

How Does Laser Cutting Protective Film Work?

What are the uses of PTFE rod?

What is PTFE Sheet Used For?

The Essential Guide to Industrial Water Pipes

Once the trench is prepared, it's time to begin connecting the corrugated HDPE pipe. Start by connecting the pieces of pipe using the manufacturer's recommended methods, such as a snap or gasket joint. Make sure the pipes are properly aligned and securely connected to prevent any leaks or damage.

5. Backfilling .

After the pipe is connected, it's time to backfill the trench. Use a suitable material, such as sand or gravel, to fill in the space around the pipe. Make sure to compact the backfill material to provide support and stability for the pipe. It's important to avoid using sharp or heavy materials that could damage the pipe.

6. Testing .

Before completing the installation process, it's important to test the corrugated HDPE pipe to ensure it is functioning properly. Use a pressure test or visual inspection to check for any leaks or issues. Make any necessary adjustments or repairs before backfilling the trench.

7. Finishing Up .

Once the installation is complete and the pipe has been tested, it's time to finish up the project. Make sure to properly compact the backfilled trench to prevent settling or erosion. Restore any landscaping or surfaces that were disturbed during the installation process.

Remember, proper installation of corrugated HDPE pipe is crucial for the success of your project. If you have any questions or need assistance with the installation process, don't hesitate to contact us for support. Our experienced team is here to help you every step of the way. So, choose a reliable supplier and get started on your project today!

For more information, please visit used hdpe pipe for sale, floaters manufacturer, High Density Polyethylene(HDPE) Pipes And Fittings Solutions Provider.

Explore more:What is the cheapest plastic sheet?

What is fluorine rubber used for?

What is the introduction of polystyrene?

What does NBR mean in oil seal?

Is HDPE Gas Line the Revolutionary Solution for Environmentally-Friendly Energy Distribution?

What are the elements of Teflon?

Does HDPE pipe leach chemicals?