Is Non Sparking Hammer the Top Choice for Safety?

Is Non Sparking Hammer the Top Choice for Safety?

In many industrial settings, the risk of sparks igniting flammable gases or liquids is a major concern. When using traditional hammers made of steel, the friction between the hammer and the object being struck can create sparks, potentially leading to a dangerous situation. This is where non sparking hammers come into play.

Non sparking hammers are specially designed tools that are made from non-ferrous materials such as copper, brass, or aluminum bronze. These materials are softer than traditional steel, which means they do not create sparks when struck against another object. This makes non sparking hammers the top choice for safety in environments where the risk of fire or explosion is high.

The Rise of Synthetic Fiber Brushes: A Revolution in Painting

Enhancing Surfaces with Wood Graining Tools: A Masterstroke of Artistry

The Non-Sparking Hammer: Ensuring Safety in Hazardous Environments

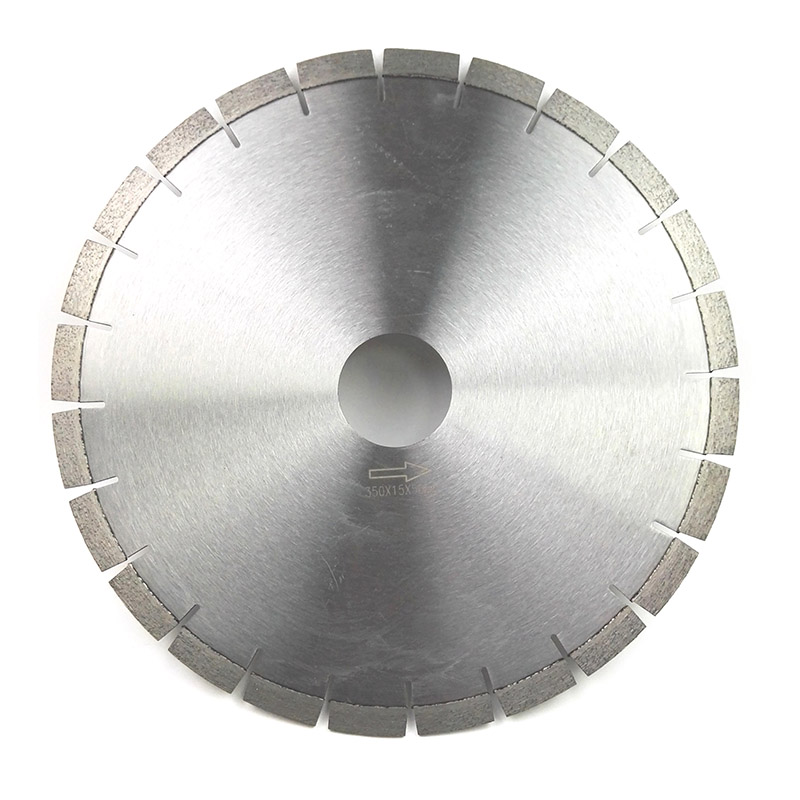

How many teeth do I need on my saw blade?

Do patterned paint rollers work?

The Intricate Art of Diamond Saw Blade Manufacturing

What are diagonal pliers best used for?

The key to the safety of non sparking hammers lies in the materials they are made from. Copper, brass, and aluminum bronze are all non-ferrous metals, which means they do not produce sparks when struck. This is crucial in environments where flammable gases or liquids are present, as even a small spark can have catastrophic consequences. By using non sparking hammers, workers can reduce the risk of accidents and create a safer work environment.

Furthermore, non sparking hammers are also designed with safety in mind. Their construction is often different from traditional hammers, with features such as anti-spark heads and ergonomic handles to further reduce the risk of accidents. This attention to detail in the design of non sparking hammers makes them not only safer to use but also more comfortable and efficient for workers.

In conclusion, non sparking hammers are indeed the top choice for safety in environments where sparks can have serious consequences. Their non-ferrous materials prevent the creation of sparks, reducing the risk of fire or explosion. Additionally, the design of non sparking hammers focuses on safety, with features that further minimize the risk of accidents. By choosing non sparking hammers, workers can protect themselves and their surroundings, creating a safer and more efficient work environment.

For more Non-Sparking Tightening Tools, Brass Hammer manufacturer, Non-Sparking Impact Socketsinformation, please contact us. We will provide professional answers.

Explore more:What are the applications of TCT tools?

Pattern Rollers: Transforming Surfaces with Artistic Imprints

Which Non-Sparking Brass Hammer is best for hand safety?

How Do I Choose a Weldon End Mill Holder?

Which is the Best Beryllium Hammer for Business Success?

How long will a diamond blade last?

What is a cordless drill best used for?