Maximizing Automation Efficiency with Rotary Actuators/Air Grippers

Maximizing Automation Efficiency with Rotary Actuators/Air Grippers.

In today’s fast-paced industrial world, automation has become an essential part of manufacturing operations. With increasing demands for efficiency and productivity, companies are constantly seeking ways to maximize automation efficiency. One such way is through the use of rotary actuators and air grippers.

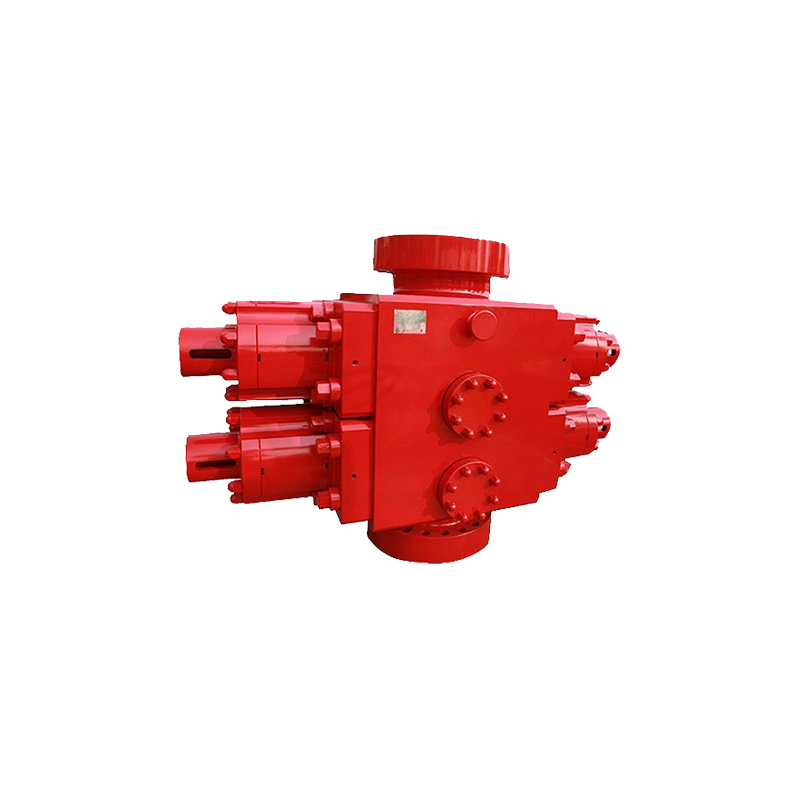

Rotary actuators are devices that convert hydraulic, pneumatic or electric power into mechanical motion. They are commonly used in automation systems to control the rotation of components, such as valves, pumps, and cylinders. Air grippers, on the other hand, are devices that use compressed air to open and close gripper jaws. They are used in automation systems to handle parts and products.

The use of rotary actuators and air grippers in automation systems can greatly increase efficiency. By automating tasks that were previously done manually, companies can save time and money while improving the accuracy and consistency of their manufacturing processes. For example, using an air gripper to handle parts can eliminate the need for a worker to physically pick up and place the parts, which can be time-consuming and tiring. Additionally, rotary actuators can be used to precisely control the speed and position of components, improving the quality and consistency of the finished products.

Explore more:What Is the Best Seal for a Rotating Shaft?

Applications and Benefits of Pallet Inverters

The Ultimate Guide to Lamination Welding: A Comprehensive Overview

Applications of Load Wheel Side Rollers

What is the difference between angular contact bearing and ball bearing?

What are sanitary diaphragm pumps and how do they work?

Why are slurry pumps essential for mining and mineral processing operations?

Moreover, the integration of rotary actuators and air grippers with other automation components such as sensors, controllers, and software can further improve efficiency. Automated systems can detect and correct errors in real-time, increasing accuracy and reducing waste. Furthermore, data collected from automation systems can be used to analyze and optimize manufacturing processes, leading to continuous improvement.

In conclusion, the use of rotary actuators and air grippers in automation systems is a simple yet effective way to maximize efficiency and productivity. By automating tasks, improving accuracy and consistency, and integrating with other automation components, companies can save time and money while improving the quality of their products. With advancements in technology and increasing demands for efficiency, the use of automation in manufacturing operations will continue to grow.

If you want to learn more, please visit our website Rotary Actuators/ Air gripper, Directional Control Valve Export, High Pressure Electro-Pneumatic Regulator.

Explore more:Common Types of Gate Valves

Different Types of Belleville Washers and Their Advantages

What is hydraulic directional control valve?

Natural Gas Y Strainer: Ensuring Optimal Gas Flow and Efficiency

What is API 6D ball valve?

Hydraulic Rubber Seal: Ensuring Efficiency and Reliability in Hydraulic Systems

Factors to Consider When Choosing a Filter Press Feed Pump