Revolutionize Your Metal Fabrication Business with Sheet Metal Bending Machine - Is it Worth the Investment?

Hisman are exported all over the world and different industries with quality first. Our belief is to provide our customers with more and better high value-added products. Let's create a better future together.

You will get efficient and thoughtful service from Hisman.

Sheet metal bending machines are automated tools that use computer numerical control (CNC) systems to bend metal sheets with accuracy and consistency. These machines offer a wide range of benefits that can greatly improve the efficiency and quality of your metal fabrication business. But is it worth the investment? Let's dive into the reasons why investing in a sheet metal bending machine can take your business to the next level.

1. Increased Efficiency.

One of the most significant benefits of using a sheet metal bending machine is the increased efficiency it brings to your fabrication process. These machines are capable of bending metal sheets at a much faster rate than manual methods, which means you can produce more parts in less time. This efficiency not only allows you to fulfill orders faster but also enables you to take on more projects and increase your overall output.

2. Greater Precision.

Precision is key in metal fabrication, especially when it comes to bending metal sheets. Manual bending methods can be inconsistent and prone to human error, leading to inaccuracies in the final product. Sheet metal bending machines, on the other hand, offer precision and repeatability, ensuring that each part is bent to the exact specifications every time. This level of accuracy not only improves the quality of your products but also minimizes material waste, saving you time and money in the long run.

Explore more:Do patterned paint rollers work?

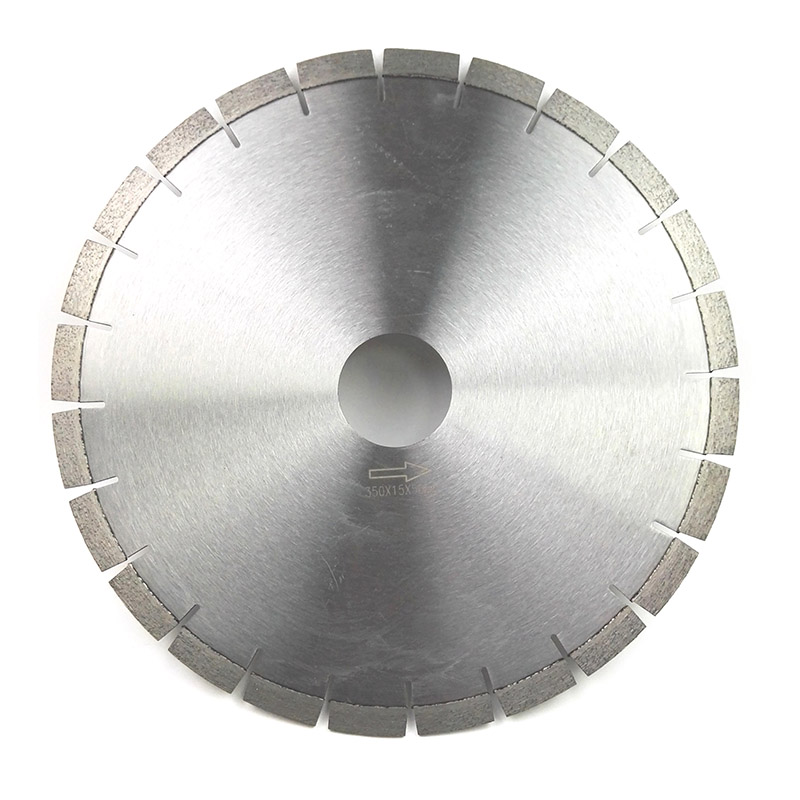

The Intricate Art of Diamond Saw Blade Manufacturing

What are diagonal pliers best used for?

What are the applications of TCT tools?

Pattern Rollers: Transforming Surfaces with Artistic Imprints

Which Non-Sparking Brass Hammer is best for hand safety?

How Do I Choose a Weldon End Mill Holder?

3. Versatility.

Sheet metal bending machines are versatile tools that can be used to bend a wide range of materials, including aluminum, stainless steel, and copper. Whether you're working on thin sheets for electrical enclosures or thick plates for structural components, these machines can handle the job with ease. Additionally, many sheet metal bending machines come equipped with multiple tooling options, allowing you to create a variety of bends and shapes to meet your customers' unique requirements.

4. Cost Savings.

While the initial investment in a sheet metal bending machine may seem high, it can actually save you money in the long run. By increasing efficiency and reducing material waste, these machines help you complete projects faster and with greater accuracy, ultimately lowering production costs. Additionally, the versatility of sheet metal bending machines allows you to take on a wider range of projects, attracting new customers and increasing your overall revenue.

5. Improved Safety.

Manual bending methods can be physically demanding and pose a risk of injury to your employees. Sheet metal bending machines eliminate the need for manual labor, reducing the risk of accidents and creating a safer working environment for your team. With automated controls and safety features built-in, these machines ensure that your employees can operate them with minimal risk, giving you peace of mind knowing that your workforce is protected.

In conclusion, investing in a sheet metal bending machine can revolutionize your metal fabrication business in more ways than one. From increased efficiency and precision to cost savings and improved safety, the benefits of using these machines are undeniable. If you're looking to take your business to the next level and stay ahead of the competition, consider adding a sheet metal bending machine to your arsenal. With the right machine and proper training, you can boost productivity, enhance the quality of your products, and ultimately grow your bottom line.

If you want to learn more, please visit our website appliance doors bending machine, aluminum door panel bender.

Explore more:Which is the Best Beryllium Hammer for Business Success?

How long will a diamond blade last?

What is a cordless drill best used for?

Non-Sparking Sockets and Accessories: A Crucial Component for Safety

How to Make Circular Saw Blades Last Longer?

Corded vs Cordless Tools - Which is Better?

The Art of Precision: Enhancing Walls with Paint Tape