Understanding Recyclable Shrink Films: Polyolefin vs ...

Understanding Recyclable Shrink Films: Polyolefin vs ...

What is shrink film?

Understanding Recyclable Shrink Films: Polyolefin vs ...

What is shrink film?

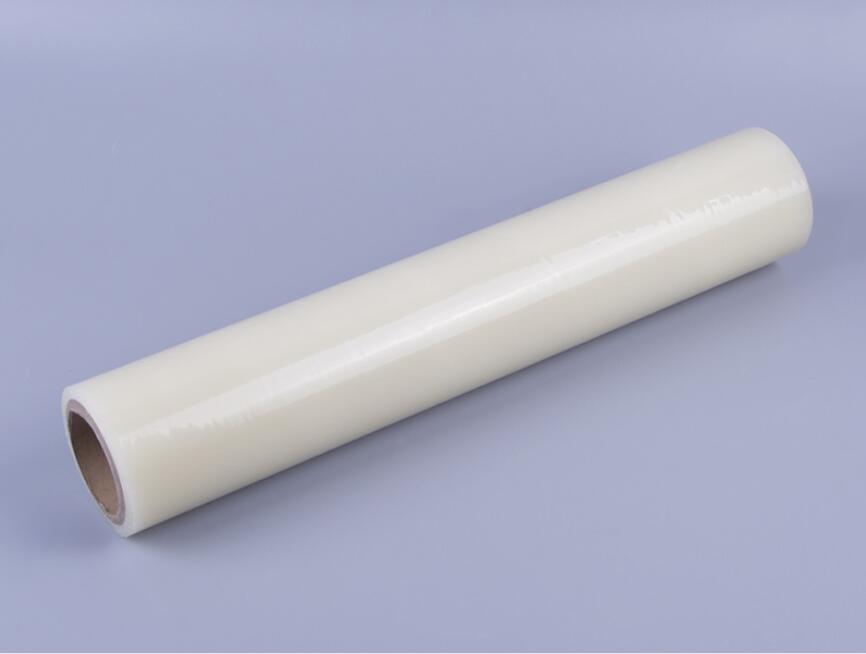

Shrink film is a highly versatile packaging material that is widely used in the manufacturing and packaging industries. It is a plastic film that shrinks when heated and can be wrapped tightly around products to form a protective barrier. Shrink film is commonly used to bundle items such as bottles, cans, and boxes, or to completely wrap and protect equipment, electronics, and other products from moisture, dust, or damage during shipping and handling.

What are the raw materials used in shrink film?

Shrink films can be made from different materials, including polyolefin (POF) and polyvinyl chloride (PVC), which have different performance characteristics and therefore different environmental impacts. The purpose of this paper is to provide an overview of the two main types of shrink wrap, polyolefin and PVC, their properties, and their environmental impact. In addition, the recycling process for these films will be discussed, as well as the potential for other recyclable shrink films.

A Comparison of Recycled Polyolefin Shrink Film and PVC Shrink Film: Advantages and Benefits

FeaturesRecycled Polyolefin Shrink FilmPVC Shrink FilmEnvironmental friendlinessRecyclable, free of hazardous materialsContains hazardous materials, difficult to decomposeSafetyNon-toxic, does not release harmful gases when heatedContains chlorine gas, and releases harmful gases when heatedDurabilityTear-resistant, impact-resistant, moisture-proof, waterproofEasily torn, prone to damagePackaging effectHigh transparency and flexibilityColorful but lower transparencyCost-effectivenessRelatively lowRelatively highRecycled Polyolefin Shrink Film has more advantages and benefits compared to PVC Shrink Film. Recycled Polyolefin Shrink Film is a more environmentally friendly, safer, more durable, and better packaging solution with lower costs. Meanwhile, PVC Shrink Film contains hazardous materials and is prone to cause environmental pollution. Therefore, Recycled Polyolefin Shrink Film is a better substitute and an important direction for sustainable packaging in the future.

Polyolefin shrink film (POF shrink film)

Polyolefin (POF) is a plastic polymer made from petroleum, natural gas, or other hydrocarbon sources. It is a widely used shrink film material because of its excellent sealing and shrinking properties, flexibility, and high transparency. polyolefin heat shrink film manufacturer is available in a variety of forms, including single or multi-layer films, with different thicknesses, transparency, and performance characteristics.

Polyolefin shrink film has a low shrink tension, which means it can wrap products without much force or pressure, and it adapts well to the shape of the product. In addition, polyolefin shrink film has a high puncture and tear resistance, which protects the product from damage during shipping and storage.

Benefits of using recycled shrink film

One of the main benefits of polyolefin shrink film is that it can be recycled. Recyclable polyolefin shrink film can be processed into other forms of plastic, such as bags, traffic cones, or irrigation tubing. As a result, this makes them a more environmentally friendly option than other types of shrink film that are not easily recycled or simply cannot be recycled.

Recycling process

The recycling process involves collecting, grinding, and melting the polyolefin shrink film. First, the collected shrink film is sorted and cleaned to remove any contaminants, such as dust or food residue. The film is then ground into small flakes or pellets that are used as feedstock for the new product. These flakes are then melted, extruded or injection molded into different forms of plastic products.

what applications can biodegradable and recyclable polyolefin shrink film be used for?

Biodegradable and recyclable polyolefin shrink film is usually used for packaging consumer products, such as food, beverage, cosmetics, pharmaceuticals, household products, pizza packaging film,fruit packaging film, egg packaging film, etc. It has high transparency, excellent shrinkage performance, good abrasion, and tear resistance, and can also be recycled in an environmentally friendly manner, so it is widely used in various packaging industries.

colored shrink wrap

Polyvinyl chloride shrink film

Another commonly used plastic film often used for packaging is polyvinyl chloride (PVC) shrink film, a synthetic plastic polymer derived from fossil fuels that have many desirable properties such as flexibility, transparency, and toughness. Because of these properties, PVC shrink film is often chosen for products that require a high degree of visual appeals, such as cosmetics, electronics, and other consumer products.

Characteristics of PVC Shrink Film

Compared to polyolefins, PVC shrink film has a higher shrink tension, which means it requires more heat and pressure to shrink around the product. In addition, PVC shrink film is more rigid, making it more difficult to wrap irregularly shaped products. While it has high clarity and gloss, it is not as strong and durable as polyolefin shrink film, making it more susceptible to tearing or puncturing.

Challenges in recycling PVC shrink film

A major challenge with PVC shrink film is that it is difficult to recycle because of its chemical composition. When PVC is heated, it emits toxic gases that can be harmful to the environment and human health. Therefore, recycling PVC shrink film requires specialized equipment and processes to ensure that these toxic gases are captured and neutralized.

Health and Environmental Concerns

PVC shrink film is known to contain chemicals that are potentially harmful to human health and the environment, including phthalates and lead. Phthalates are added to PVC to improve its flexibility and durability, but they can leach out of the material over time, which can affect hormones or damage organs. Meanwhile, lead is added to PVC as a stabilizer, but it can accumulate in the environment and cause neurological and behavioral problems.

Recyclable Shrink Film

In addition to the two types of shrink film mentioned above, there are other types of recyclable shrink film on the market. Examples include PETG shrink film, which is known for its uniformity, high gloss, and clarity; PLA shrinks film, which is plant-based and biodegradable, although it is not widely accepted by recycling organizations; and bio-PET shrink film, which is made from a blend of plant-based bio-based PET and fossil fuel-based PET.

Comparison of different types of recyclable shrink films

Different types of recyclable shrink films have their own advantages and disadvantages. For example, PETG is a safe material that can be easily recycled, but it is more expensive than other shrink films. PLA shrink film is biodegradable, but requires specialized equipment to recycle and is also more expensive than polyolefin shrinks film. Finally, bio-PET shrink film is not as environmentally friendly as PLA, but it is cheaper and more acceptable.

Why choose biodegradable and recyclable POF to shrink film?

Choosing biodegradable recyclable POF shrink films can reduce environmental pollution because they are made from renewable natural resins or starch, which decompose faster than traditional POF plastic films. In addition, this type of POF film can also be recycled, further reducing environmental pollution because recycling and reusing discarded plastic products can reduce the environmental impact caused by landfills and incineration. Finally, biodegradable and recyclable POF shrink film also offers superior performance and longevity while meeting environmental requirements.

How is shrink film made?

Shrink film is produced through a four-step process.

Step 1: Polypropylene (POF) pellets are placed into an extruder, heated, and melted.

Step 2: The melted polypropylene is extruded through a die to form a thin film.

Step 3: The extruded film is cooled and solidified using cooling rolls or water quenching.

Step 4: The solidified film undergoes stretching and shaping processes to achieve the desired shrinkability and dimensions.

FAQ

Is shrink film recyclable?

Shrink films made from certain materials can be recycled, such as polyethylene (PE) and polypropylene (PP). However, it's important to check with your local recycling facility to see if they accept these types of plastics. PVC shrink film is not widely recyclable and can release toxic chemicals when burned.

Is shrink film eco-friendly?

Shrink film is generally not considered eco-friendly because it is made from plastic, which is derived from non-renewable resources and does not biodegrade easily. However, there are more environmentally-friendly options available, such as bio-based or biodegradable shrink films, that have a lower carbon footprint and reduce plastic waste in the environment.

What is the eco-friendly shrink wrap film?

An eco-friendly shrink wrap film is one that is biodegradable, compostable, or made from renewable resources. These types of shrink films break down naturally in the environment, reducing waste and environmental pollution. Some examples include shrink films made from plant-based materials like PLA or PHA.

Is polyolefin shrink film recyclable?

Polyolefin shrink film, which includes polyethylene and polypropylene, is widely recyclable in many areas. Polyethylene terephthalate glycol (PETG) is another type of shrink film that is recyclable and has a lower carbon footprint than other types of plastics.

Is polyolefin shrink film eco-friendly?

Polyolefin shrink film is considered to be more eco-friendly than other types of shrink films because it is recyclable and does not emit harmful chemicals during production or disposal. However, the impact on the environment depends on the source of the raw materials used to make the product.

Is Shrinky Dink plastic recyclable?

Shrinky Dink plastic, which is a type of polystyrene plastic, is not commonly recycled in most areas. However, some manufacturers offer recycling programs for Shrinky Dink plastic products, or you can repurpose them for other projects to reduce waste.

Can you print on Bopp?

What are the types of cell culture consumables?

Are biodegradable plastic bags eco-friendly?

The Types of Self-Adhesive Graphic Film

What Sausage Casings Are Made of?

What are Benefits of PET Protective Film?

What are the packaging materials for tea?

Shrink film is a highly versatile packaging material that is widely used in the manufacturing and packaging industries. It is a plastic film that shrinks when heated and can be wrapped tightly around products to form a protective barrier. Shrink film is commonly used to bundle items such as bottles, cans, and boxes, or to completely wrap and protect equipment, electronics, and other products from moisture, dust, or damage during shipping and handling.

What are the raw materials used in shrink film?

Shrink films can be made from different materials, including polyolefin (POF) and polyvinyl chloride (PVC), which have different performance characteristics and therefore different environmental impacts. The purpose of this paper is to provide an overview of the two main types of shrink wrap, polyolefin and PVC, their properties, and their environmental impact. In addition, the recycling process for these films will be discussed, as well as the potential for other recyclable shrink films.

A Comparison of Recycled Polyolefin Shrink Film and PVC Shrink Film: Advantages and Benefits

FeaturesRecycled Polyolefin Shrink FilmPVC Shrink FilmEnvironmental friendlinessRecyclable, free of hazardous materialsContains hazardous materials, difficult to decomposeSafetyNon-toxic, does not release harmful gases when heatedContains chlorine gas, and releases harmful gases when heatedDurabilityTear-resistant, impact-resistant, moisture-proof, waterproofEasily torn, prone to damagePackaging effectHigh transparency and flexibilityColorful but lower transparencyCost-effectivenessRelatively lowRelatively highRecycled Polyolefin Shrink Film has more advantages and benefits compared to PVC Shrink Film. Recycled Polyolefin Shrink Film is a more environmentally friendly, safer, more durable, and better packaging solution with lower costs. Meanwhile, PVC Shrink Film contains hazardous materials and is prone to cause environmental pollution. Therefore, Recycled Polyolefin Shrink Film is a better substitute and an important direction for sustainable packaging in the future.

Polyolefin shrink film (POF shrink film)

Polyolefin (POF) is a plastic polymer made from petroleum, natural gas, or other hydrocarbon sources. It is a widely used shrink film material because of its excellent sealing and shrinking properties, flexibility, and high transparency. polyolefin heat shrink film manufacturer is available in a variety of forms, including single or multi-layer films, with different thicknesses, transparency, and performance characteristics.

Polyolefin shrink film has a low shrink tension, which means it can wrap products without much force or pressure, and it adapts well to the shape of the product. In addition, polyolefin shrink film has a high puncture and tear resistance, which protects the product from damage during shipping and storage.

Benefits of using recycled shrink film

One of the main benefits of polyolefin shrink film is that it can be recycled. Recyclable polyolefin shrink film can be processed into other forms of plastic, such as bags, traffic cones, or irrigation tubing. As a result, this makes them a more environmentally friendly option than other types of shrink film that are not easily recycled or simply cannot be recycled.

Recycling process

The recycling process involves collecting, grinding, and melting the polyolefin shrink film. First, the collected shrink film is sorted and cleaned to remove any contaminants, such as dust or food residue. The film is then ground into small flakes or pellets that are used as feedstock for the new product. These flakes are then melted, extruded or injection molded into different forms of plastic products.

what applications can biodegradable and recyclable polyolefin shrink film be used for?

Biodegradable and recyclable polyolefin shrink film is usually used for packaging consumer products, such as food, beverage, cosmetics, pharmaceuticals, household products, pizza packaging film,fruit packaging film, egg packaging film, etc. It has high transparency, excellent shrinkage performance, good abrasion, and tear resistance, and can also be recycled in an environmentally friendly manner, so it is widely used in various packaging industries.

colored shrink wrap

Polyvinyl chloride shrink film

Another commonly used plastic film often used for packaging is polyvinyl chloride (PVC) shrink film, a synthetic plastic polymer derived from fossil fuels that have many desirable properties such as flexibility, transparency, and toughness. Because of these properties, PVC shrink film is often chosen for products that require a high degree of visual appeals, such as cosmetics, electronics, and other consumer products.

Characteristics of PVC Shrink Film

Compared to polyolefins, PVC shrink film has a higher shrink tension, which means it requires more heat and pressure to shrink around the product. In addition, PVC shrink film is more rigid, making it more difficult to wrap irregularly shaped products. While it has high clarity and gloss, it is not as strong and durable as polyolefin shrink film, making it more susceptible to tearing or puncturing.

Challenges in recycling PVC shrink film

Are you interested in learning more about petg manufacturers? Contact us today to secure an expert consultation!

A major challenge with PVC shrink film is that it is difficult to recycle because of its chemical composition. When PVC is heated, it emits toxic gases that can be harmful to the environment and human health. Therefore, recycling PVC shrink film requires specialized equipment and processes to ensure that these toxic gases are captured and neutralized.

Health and Environmental Concerns

PVC shrink film is known to contain chemicals that are potentially harmful to human health and the environment, including phthalates and lead. Phthalates are added to PVC to improve its flexibility and durability, but they can leach out of the material over time, which can affect hormones or damage organs. Meanwhile, lead is added to PVC as a stabilizer, but it can accumulate in the environment and cause neurological and behavioral problems.

Recyclable Shrink Film

In addition to the two types of shrink film mentioned above, there are other types of recyclable shrink film on the market. Examples include PETG shrink film, which is known for its uniformity, high gloss, and clarity; PLA shrinks film, which is plant-based and biodegradable, although it is not widely accepted by recycling organizations; and bio-PET shrink film, which is made from a blend of plant-based bio-based PET and fossil fuel-based PET.

Comparison of different types of recyclable shrink films

Different types of recyclable shrink films have their own advantages and disadvantages. For example, PETG is a safe material that can be easily recycled, but it is more expensive than other shrink films. PLA shrink film is biodegradable, but requires specialized equipment to recycle and is also more expensive than polyolefin shrinks film. Finally, bio-PET shrink film is not as environmentally friendly as PLA, but it is cheaper and more acceptable.

Why choose biodegradable and recyclable POF to shrink film?

Choosing biodegradable recyclable POF shrink films can reduce environmental pollution because they are made from renewable natural resins or starch, which decompose faster than traditional POF plastic films. In addition, this type of POF film can also be recycled, further reducing environmental pollution because recycling and reusing discarded plastic products can reduce the environmental impact caused by landfills and incineration. Finally, biodegradable and recyclable POF shrink film also offers superior performance and longevity while meeting environmental requirements.

How is shrink film made?

Shrink film is produced through a four-step process.

Step 1: Polypropylene (POF) pellets are placed into an extruder, heated, and melted.

Step 2: The melted polypropylene is extruded through a die to form a thin film.

Step 3: The extruded film is cooled and solidified using cooling rolls or water quenching.

Step 4: The solidified film undergoes stretching and shaping processes to achieve the desired shrinkability and dimensions.

FAQ

Is shrink film recyclable?

Shrink films made from certain materials can be recycled, such as polyethylene (PE) and polypropylene (PP). However, it's important to check with your local recycling facility to see if they accept these types of plastics. PVC shrink film is not widely recyclable and can release toxic chemicals when burned.

Is shrink film eco-friendly?

Shrink film is generally not considered eco-friendly because it is made from plastic, which is derived from non-renewable resources and does not biodegrade easily. However, there are more environmentally-friendly options available, such as bio-based or biodegradable shrink films, that have a lower carbon footprint and reduce plastic waste in the environment.

What is the eco-friendly shrink wrap film?

An eco-friendly shrink wrap film is one that is biodegradable, compostable, or made from renewable resources. These types of shrink films break down naturally in the environment, reducing waste and environmental pollution. Some examples include shrink films made from plant-based materials like PLA or PHA.

Is polyolefin shrink film recyclable?

Polyolefin shrink film, which includes polyethylene and polypropylene, is widely recyclable in many areas. Polyethylene terephthalate glycol (PETG) is another type of shrink film that is recyclable and has a lower carbon footprint than other types of plastics.

Is polyolefin shrink film eco-friendly?

Polyolefin shrink film is considered to be more eco-friendly than other types of shrink films because it is recyclable and does not emit harmful chemicals during production or disposal. However, the impact on the environment depends on the source of the raw materials used to make the product.

Is Shrinky Dink plastic recyclable?

Shrinky Dink plastic, which is a type of polystyrene plastic, is not commonly recycled in most areas. However, some manufacturers offer recycling programs for Shrinky Dink plastic products, or you can repurpose them for other projects to reduce waste.

For more Excellent Transparency PVC Shrink Filminformation, please contact us. We will provide professional answers.

What is co-extruded film in food packaging?

The Benefits of Printed Shrink Film

The Difference Between Natural Casing and Artificial Casing

What is anti-static film?

How do you know if a plastic bucket is food grade?

What Is A Dropper Bottle Called?

What Makes Perfume Bottles So Captivating?

- 51

- 0

- 0