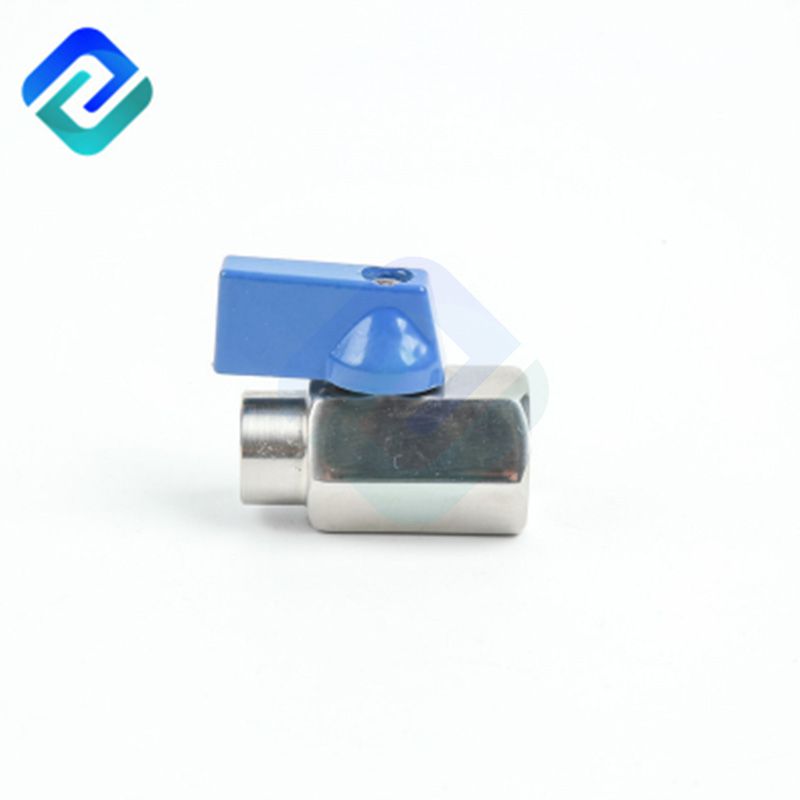

Unveiling the Three Piece Trunnion Valve

The three piece trunnion valve is a crucial component for controlling the flow of fluids or gases in different industrial applications. In this article, we will walk you through the step-by-step process of unveiling the three piece trunnion valve.

Step 1: Gather Required Tools and Equipment.

To unveil the three piece trunnion valve, you will need some essential tools and equipment, including protective gloves, goggles, a wrench, a crane or hoist, a lubricant, and cleaning materials.

Step 2: Disconnect the Piping System.

Before removing the three piece trunnion valve, ensure that the piping system is disconnected from the valve to avoid any leakages.

Step 3: Position the Valve.

Position the valve properly, ensuring that the flange faces are parallel to the pipeline and use the crane or hoist to hold it in place.

Step 4: Loosen and Remove the Bolts.

Use the wrench to loosen and remove the bolts holding the valve in place. Ensure that you keep the bolts and nuts safely for future use.

Step 5: Separate the Valve Body and End Caps.

Gently separate the valve body from the end caps using the crane or hoist to avoid any damages to the trunnion shaft and seals.

Step 6: Inspect the Valve Components.

Explore more:Adjustable Choke Valve: The Key to Controlling Flow in Oil & Gas Operations

Thread Type Globe Valve vs. Flanged Globe Valve: Which One to Choose?

How to Save Money When Choosing Nozzle Check Valves in Malaysia?

How 63mm Gate Valves Revolutionize Fluid Control?

Everything You Need To Know To Find The Best Smt Nozzle Manufacturer

Weir Type Diaphragm Valve: A Reliable Solution for Flow Control

Plug Valves: Versatile Flow Control Solutions

After separating the valve components, inspect the trunnion shaft, end caps, and valve seals for any damages or wear and tear. Replace any damaged components with new ones.

Step 7: Clean the Valve Components.

Use cleaning materials to remove any dirt, debris, or residues on the valve components. This will help to prevent contamination and ensure smooth operation of the valve.

Step 8: Apply Lubricant.

Use a lubricant to lubricate the trunnion shaft and valve seals for smooth and efficient operation of the valve.

Step 9: Reassemble the Valve Components.

After the inspection, cleaning, and lubrication process, reassemble the valve components by placing the end caps on both sides of the valve body and tightening the bolts.

Step 10: Reconnect the Piping System.

Once the valve is reassembled, reconnect the piping system and ensure that it is well aligned and tightened to avoid any leakages.

Conclusion:

Unveiling the three piece trunnion valve is an intricate process that requires careful attention to detail. By following the above-mentioned step-by-step process, you can ensure that the valve operates smoothly and efficiently. Proper maintenance and cleaning of the valve components can help to extend the longevity and performance of the valve.

Want more information on Three Piece Trunnion Mounted Ball Valve, 2" 2 Piece Trunnion Mounted Ball Valve Company in China, China API 6D fully welded ball valve manufacturer? Feel free to contact us.

Explore more:High-Pressure Quick Connect Nozzle Spray Gun: The Ultimate Tool for Efficient Cleaning

The Advantages of Overhead Conveyor Bearings in Industrial Automation

Choosing the Right Activated Carbon Filter for Your Needs

Drum Gear Coupling: The Backbone of Efficient Power Transmission

Mud Desander: Enhancing Drilling Fluid Management in Oil and Gas Operations

Centrifugal Pumps: Harnessing the Power of Fluid Dynamics

What is a waste heat recovery boiler and how does it work?