What is a PE Film?

Polyethylene, commonly referred to as PE, is one of the most widely used polymers in various industries today. It is a thermoplastic polymer that can be melted and re-molded repeatedly without undergoing any significant chemical change. PE films are thin sheets of polyethylene that find applications in packaging, agriculture, construction, and many other sectors. In this article, we will delve into the details of what a PE film is and its wide-ranging applications.

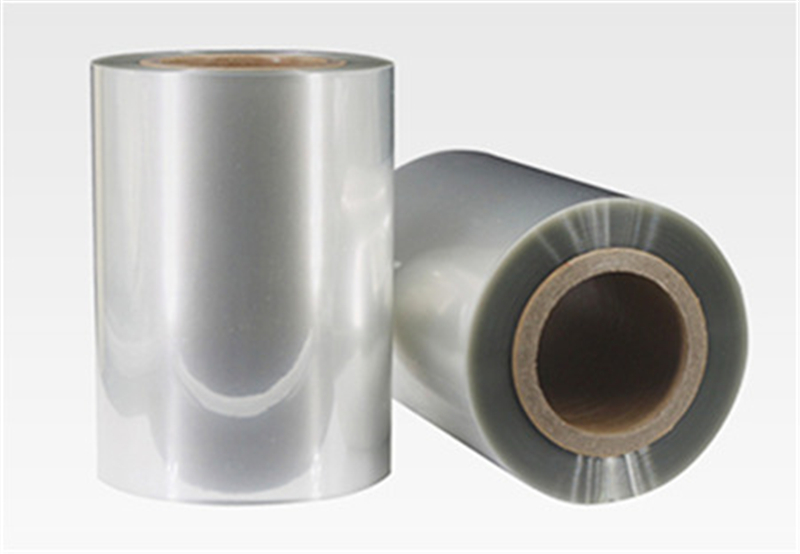

PE films are manufactured by the process of extrusion, where resins are melted and then forced through a die, resulting in a continuous thin sheet. The thickness of the film can range from as thin as 0.25 mils to as thick as 10 mils, depending on its intended use. These films can be transparent, translucent, or opaque, and they can also be colored or printed upon if required.

One of the notable features of PE films is its versatility. It comes in various types, including low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), and high-density polyethylene (HDPE). Each type varies in terms of its mechanical properties, such as tensile strength, tear resistance, and impact resistance. Furthermore, the films can be customized with additional attributes like UV stabilization, anti-static properties, and fire retardancy to meet specific industry needs.

High-quality PE film exhibits outstanding properties that make it an excellent choice for diverse applications. It offers excellent flexibility, making it suitable for products that require folding, wrapping, or conforming to irregular shapes. PE films provide excellent moisture resistance and serve as a barrier against gases and chemicals, protecting the packaged goods from environmental factors and ensuring their integrity. Additionally, PE films have good heat-sealing properties, enabling them to be easily sealed to create a secure and tamper-proof packaging solution.

Explore more:IML Ice Cream Containers: Combining Functionality and Aesthetics

Choosing the Right Glass Liquor Bottle

How to Use Microwave Greaseproof Kraft Paper Bags?

Applications of Retort Pouches

How is metallized paper produced?

Pet Foods Packaging: Ensuring Quality and Convenience for Your Furry Friends

Are child-resistant tins safe for children?

The benefits of PE films are not limited to just packaging applications. In agriculture, LDPE films are extensively used as greenhouse covers to control the microclimate and protect crops from adverse weather conditions. These films allow optimal light transmission, heat retention, and moisture control, creating an ideal environment for plant growth. In construction, LLDPE films are commonly used as vapor barriers to prevent the ingress of moisture into buildings, which helps in maintaining the structural integrity.

PE films also find applications in the medical industry, where their high chemical resistance and low toxicity make them suitable for medical packaging, such as sterile pouches or bags. Moreover, these films are used in the manufacturing of disposable gloves and protective clothing, providing a reliable barrier against infectious agents. In the electronics industry, antistatic PE films are used for protecting sensitive electronic components during transportation or storage, preventing damage caused by electrostatic discharge.

In conclusion, a PE film is an incredibly versatile and adaptable material that finds extensive use in various industries. Its ability to be molded, colored, and customized to meet specific requirements makes it a suitable choice for a wide range of applications. Whether it is for packaging, agriculture, construction, or medical purposes, high-quality PE films offer excellent protection, sealing capabilities, and durability. If you are looking for a reliable PE film supplier, please do not hesitate to contact us.

Sustainable Packaging Solutions: Promoting Eco-Friendly Practices

What is cold forming process in blister packaging?

What are Sausage Casings Made of?

What Size Tarp for Camping?

When Should You Consider Using Eco-Solvent Ink for Your Printing Projects?

Water Bottle Sport Cap: Enhancing Hydration On-the-Go

Advantages and Applications of Sticky Sublimation Paper