What Is Injection Moulding? Uses, Advantages & ...

What Is Injection Moulding? Uses, Advantages & ...

Are you interested in learning more about automotive injection molded parts? Contact us today to secure an expert consultation!

Car grilles contain plastics that are produced using injection moulding

What is Injection Moulding?

Injection moulding is the most common manufacturing process used to produce plastic parts. The process utilises a machine, raw material, and a mould of the product part being produced to consistently manufacture high volumes of identical objects at a fast rate.

Machines are categorised and rated based on their clamping pressure or tonnage. The higher the clamping pressure, the larger the machine, and the larger the parts that it is able to fabricate. Clamping pressures vary anywhere from 5 tons to 6000 tons. The clamping pressure required to give optimum results for a product part is determined by the projected area of the part in the mould. Using clamping pressures that are too high or too low for a certain part can lead to defects such as flashing, where molten material seeps out of the mould and solidifies, leading to an unwanted thin layer of material forming around the part.

The raw materials used are chosen based on the function and specifications of the final product part. However, each material also has various parameters that need to be considered within the process. Most polymers can be used in the process, including all thermoplastics (nylon, polystyrene, polyethylene) and some thermosetting plastics (epoxy, phenolic). Though being mainly used for the production of plastics, other materials may also be used with injection moulding.

The main components of the process are described below:

Injection Moulding Process

- Moulding – A mould in the shape of the product part is designed using CAD, manufactured, and split into two halves.

- Clamping – The two halves of the mould are pushed and held securely closed by the clamping unit of the machine. Larger machines will require a longer time than smaller machines to carry out this step.

- Injecting – The raw materials, usually in the form of pellets, are melted by heat and pressure, then injected into the mould very quickly, filling the entire space within it. The build-up of pressure packs and holds the material together. The exact amount of material injected in the mould is referred to as the shot.

- Cooling – The molten material within the mould begins to cool as it makes contact with the mould surfaces, solidifying into the shape of the desired part.

- Ejecting – The clamping unit separates the two halves and the cooled, finished part is ejected from the mould via the ejection unit.

The production cycle is very short, usually lasting between 2 seconds and 2 minutes. Upon the completion of step 5, the cycle restarts at step 2, manufacturing a replica of the part.

Types of Injection Moulding

There are various types of the injection moulding process, ranging from:

- Gas-assisted injection moulding

- Liquid silicone rubber injection moulding

- Cube moulding

- Die casting

- Micro injection moulding

- Reaction injection moulding

- Metal injection moulding

- Thin-wall injection moulding

Uses of Injection Moulding

Injection moulding is the preferred production method for most mass-produced plastic products, due to its high output rate and consistency of quality. These products include but are not limited to:

For more china rotational 2 shots overmold factoryinformation, please contact us. We will provide professional answers.

Explore more:Grooved Pipe Joining Technology

Ultimate Guide to Diamond Tools for Stone Polishing: Top FAQs Answered

The Benefits of Using Diamond Tools for Stone Polishing: A Comprehensive Guide

How Does BJJ Guard Work?

The Benefits of Using Drill Bit for Granite and Marble: Why You Should Make the Switch

How to Polish a concrete Floor Using Bartell Global's Metal ...

4 Advice to Choose a Drill Bit for Granite and Marble

- Automotive parts – dashboards, bumpers, grilles.

- Electronic components – electrical connectors, enclosures, protective sleeving.

- Medical devices – syringes, valves, dishes.

- Consumer plastics – mobile phone cases, bottle caps, toys.

- Furniture parts – seat cushions, chairs, seat covers.

Advantages

- Ability to use multiple materials simultaneously, including multiple types of plastic as well as multiple colours.

- Ability to design and manufacture intricate and complex geometrical shapes – as a result of the exceptionally high pressures that the moulds are applied with in the process.

- Fast production, leading to a high output rate and efficiency.

- Low labour costs due to the process being highly machine orientated.

- Repeatable process, leading to a consistent quality of products.

- Environmentally friendly process with little waste – scrap plastic is reground and re-used in the process.

- Produced parts need little work after the ejection since they have a more-or-less finished appearance.

Disadvantages

- High initial cost to set up the machinery properly.

- Not as cost effective if used to produce only a low volume of parts.

- Moulds need to be designed to a high standard, which takes skilled workers.

Considerations

There are various considerations to take into account before undertaking injection moulding, ranging from:

- Financial: The process can be costly to set up and operate, therefore it’s most suitable to those with an appropriate budget.

- Production Quantity: It’s important to take into account how many parts you wish to manufacture in order to decide whether injection moulding is the most economical production method for your product.

- Design Factors: Designing the mould itself is a key part of the process which can determine the quality and presence of defects during production. Simplifying the geometry and number of parts will lead to an easier process.

- Production Considerations: Simplifying assembly requirements, cycle times, tooling, design and the use of hot runner moulds cam all lead to cost and labour savings.

Injection moulding is just one of the processes carried out in plastic manufacturing plants. Once the plastic parts are manufactured, they are bonded together to make a product. As a result, bonding plastics is a process just as important as producing them.

The outline of injection molding

Injection molding machine is divided into 2 units i.e. a clamping unit and an injection unit.

The functions of the clamping unit are opening and closing a die, and the ejection of products. There are 2 types of clamping methods, namely the toggle type shown in the figure below and the straight-hydraulic type in which a mold is directly opened and closed with a hydraulic cylinder.

The functions of the injection unit are to melt plastic by heat and then to inject molten plastic into a mold.

The screw is rotated to melt plastic introduced from the hopper and to accumulate molten plastic in front of the screw ( to be called metering ) . After the required amount of molten plastic is accumulated, injection process is stared.

While molten plastic is flowing in a mold, the machine controls the moving speed of the screw, or injection speed. On the other hand, it controls dwell pressure after molten plastic fills out cavities.

The position of change from speed control to pressure control is set at the point where either screw position or injection pressure reaches a certain fixed value.

Contact us to discuss your requirements of thermoset injection molding. Our experienced sales team can help you identify the options that best suit your needs.

The Benefits of Using PHX Diamond Tool for Your Industrial Needs

Discover the Strength and Durability of Galvanized Taper Seat Fittings Today!

Ultimate Ornamental Iron Parts Guide: Enhance Decor with Elegance

Porous Tube: Effective Filtration Solution for Pure Water? Explore Now!

What is the maximum size of stainless steel sheet?

What are the advantages of riveting?

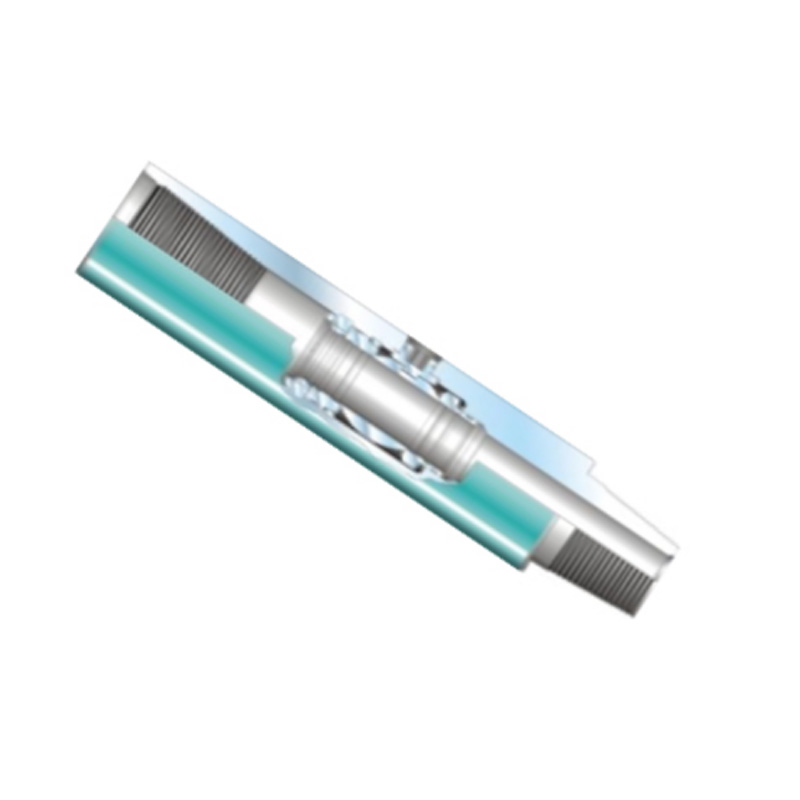

What are the advantages of purchasing electric subsurface safety valves?