What is the Advantage and Disadvantage of different types of lifts for construction

9 Types of Construction Lifts: 2022 Guide for Aerial Lifts

An aerial lift, also known as a construction lift or man lift, is a term that defines a category of equipment with an aerial platform and extension mechanism mounted on a vehicle.

The company is the world’s best different types of lifts for construction supplier. We are your one-stop shop for all needs. Our staff are highly-specialized and will help you find the product you need.

With so many different types of lifts, it’s easy to find the one that’s right for your particular job. You may use an aerial lift to:

Reach a high ceiling in a commercial building

Stock shelves in a warehouse

Conduct exterior building maintenance

Repair telephone wires

Generally, you should consider an aerial lift if you’re unable to do the job safely without one. For example, a lift is often safer and more efficient than using an extension ladder.

The Most Common Types of Aerial Lifts

There are many types of construction lifts, with each one having its own set of pros and cons. Here are nine of the most common options.

1. Articulating Boom Lifts

With an aerial platform attached to a bendable, jointed arm, articulating boom lifts have a variety of uses. And that’s especially true when you take into consideration that they can reach heights up to 100 feet.

Common uses include:

Repairs and maintenance tasks at height

When working in tight spaces

When lifting a single worker into a confined space

With the base of the arm mounted to a turntable, articulating boom lifts can make a full circular rotation. Furthermore, it has multiple joints, giving it the flexibility it needs to bend over and around obstacles.

An articulating boom lift has the potential to reach areas that other lifts can’t. This is what makes them

There are many types of lifts within the articulating category, such as atrium lifts. With four-leg mounting, they’re designed to provide elevation in small indoor spaces.

2. Telescopic Boom Lifts

Just the same as an articulating boom lift, a telescopic model can reach heights of up to 100 feet. The primary difference between the two is that a telescopic boom lift has a platform attached to an arm that moves up, down, and forward.

Here’s when it makes sense to choose a telescopic boom lift:

When working outdoors (although electric models are available for indoor use)

When you only need to lift one or two workers

When a longer reach is required

Telescopic boom lifts are the lift of choice when trimming trees or making electrical repairs at height.

These lifts are available in both electric and gas models, making them a good choice for both indoor and outdoor projects.

3. Cherry Pickers/Bucket Trucks

Some people call them bucket trucks. Others simply call them aerial lifts. Regardless of the name, these wheel vehicles come equipped with a railed aerial platform controlled by a hydraulic crane.

One of the primary benefits of a cherry picker is its ability to reach heights up to 160 feet. Common uses include:

Maintenance work

Accessing trees

Accessing utility lines

Installation and remodeling projects

Light installation

Small cherry pickers are designed to lift one person, while larger models can lift two.

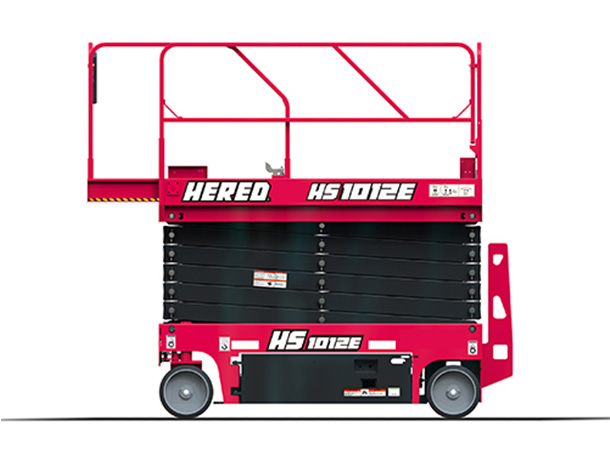

4. Electric Scissor Lifts

Wide aerial platforms, cross-brace supports, and quiet operation are just some of the many features and benefits of electric scissor lifts.

A scissor lift is designed to move straight up and down, thus allowing for safe operation in tight spots.

Unlike a boom lift, a scissor lift must be placed directly beneath the area you need to access. This is because the platform cannot move forward or backward.

With a larger platform, electric scissor lifts can transport large teams and their equipment to the necessary height (up to 60 feet).

Some of the best uses for an electric scissor lift include:

Exterior building repairs and maintenance

Window cleaning and installation

Stocking warehouse shelves

For narrow, small spaces indoors, a scissor lift is one of the most efficient ways to reach great heights.

5. Rough Terrain Scissor Lifts

Rough terrain scissor lifts work in the same way as electric scissor lifts, but there’s one big difference: they’re designed for use on rough and/or uneven terrain.

With more stable tires and a diesel engine, these lifts have the capability of tackling terrain that would bog down other machinery.

Common uses include:

Outdoor applications, especially when tackling rough terrain

Construction sites

When there’s a need to fit multiple people on the same platform

It can be frustrating to find that a worksite isn’t as accessible as you thought. Fortunately, a rough terrain scissor lift may be able to do the job.

6. Telescopic Forklifts

Telescopic forklifts are sturdy, powerful, and flexible. With an extendable boom lift and lifting attachment, you can reach heights up to 21 feet.

These machines are generally best for transporting items long distances over rough terrain. That makes them a perfect fit on construction sites.

While they’re not generally the machine of choice for lifting workers, they can be used in this fashion with the right safety measures in place.

The ability to move forward and upward makes it easy to transport large items in tight spaces and/or over rough terrain.

7. Rough Terrain Forklifts

As the name suggests, this type of forklift is designed to move items over rough terrain, such as on a construction site.

With the ability to lift loads up to 55 height, there aren’t too many tasks it can’t handle. When combined with the power to lift loads of up to 8,000 pounds, you have a machine that can be used in many different industries.

Rough terrain forklifts are perfect when conditions are less than ideal and you need both weight and height capacity working in your favor. With upward and forward reach capability, these forklifts are flexible enough to handle a variety of tasks.

8. Industrial Forklifts

Industrial forklifts are designed to move items vertically in indoor warehouses and industrial settings.

These forklifts can support up to 30,000 lbs in weight, making most lifts look simple.

The main disadvantage of industrial forklifts is a relatively short lift height, typically maxing out at 15 feet.

With so much versatility, industrial forklifts are among the most commonly purchased lifts on the market. And that holds true despite the fact that they’re used exclusively indoors.

9. Personnel Lifts

Also known as people lifts and man lifts, these are mechanical ladders that provide more stability and reach than conventional ladders.

While they appear simple to use, there’s a lot that goes into doing so safely and securely. Just the same as any other type of lift, it takes proper training to properly use personnel lifts.

These are best when you need to reach heights up to 50 feet, but don’t require the power and maneuverability of a boom or scissor lift. For example, if you need to change a lightbulb in a warehouse ceiling, a personnel lift is an easy way to do so.

How to Choose the Right Lift for Your Needs

You know you need an aerial lift for an upcoming project. But what you don’t know is which type is best. These five areas of focus will help you choose the right one:

Job site conditions: Are you working indoors or outdoors? Is the ground solid and flat, or soft and sloped?

Power source compatibility: Diesel motors are preferred for their power, but if you’re working indoors, an electric lift is often best because they’re quieter.

Movement type requirements: Do you require vertical and horizontal movement? Just vertical movement?

Weight capacity: How many people will be on the lift at once? How much equipment do you need to lift?

Space restrictions: Some lifts are bigger than others, making them more difficult to navigate in tight spaces. Know what you’re getting into before you choose a lift.

Understanding your needs within these five areas will allow you to choose a compatible lift.

Frequently Asked Questions

Buying, renting, and safely operating any type of lift comes with challenges. It’s important that you obtain as much knowledge as possible for your particular situation.

Here are some frequently asked questions regarding how to buy or rent an aerial lift:

What are the pros and cons of buying? Of renting? There are both pros and cons of each option, so comparing them will help you decide which approach to take. For instance, if money is on your mind, it’s generally more affordable to rent a lift. However, if you need it for long-term use, buying is the way to go.

Are there any benefits of buying a used lift? Buying new is likely to give you greater peace of mind, especially with a factory warranty in place, but there are benefits of buying used. Above all else, used lifts cost less than comparable new lifts. Also, if you know you won’t use the lift often, buying used allows you to get the job done without as large of a financial outlay.

Can you rent a lift? Depending on your location, there may be one or more companies in your area that rents lifts. If you don’t have the need for a lift long-term — such as if it’s for a one-off project — renting makes the most sense. It’s faster, cheaper upfront and over the long run, and saves you from conducting any maintenance on our own.

Which manufacturer of lifts is best? This is based largely on preference. Do your homework so that you can “compare apples to apples.” The internet is a great place to learn more about each manufacturer, including its reputation and top selling products. From there, compare several models in person to see which one you like best.

Now, here are some questions and answers regarding safe use of a lift:

Contact us to discuss your requirements of diesel telescopic booms. Our experienced sales team can help you identify the options that best suit your needs.

Is it safe to use a lift? The short answer is yes, but that doesn’t mean that nothing can go wrong. Maybe a worker makes a mistake, such as leaning too far over a safety rail. Or perhaps the operator of a forklift drops a load in close proximity to others. All of these accidents can result in serious injury or death. That’s why proper training and knowledge of the equipment is critical.

Do lifts require regular inspection and maintenance? Yes. If you buy a lift, it’s your responsibility to ensure that it’s regularly inspected and maintained as outlined by the manufacturer. Failure to do so can result in an accident.

What type of safety equipment is available? This depends on the type of lift, but all of them have features and add-ons designed to keep everyone on the worksite safe. Scissor lifts have guardrails that keep you from falling off the platform to the ground below.

Explore more:

Discover the Leading Metal Spinning Machinery

Which unique safety features make X-Ray Counter Machines a game changer?

How much does a fiber laser cutter cost?

Boost Productivity & Efficiency: Unleashing the Power of Caterpillar C15 for Industrial Engines

Which ISO Tank Container supplier offers the best post-purchase support?

Which dump truck brand offers the most cost-effective tonnage capacity?

Which motor is best for racing drone?

These aren’t the only questions to address when buying, renting, or operating a lift, but they’re a good starting point.

Final Thoughts

Now that you have greater knowledge of the many types of construction lifts, you can decide which one best suits your requirements.

Here are some final takeaways to keep in mind:

Even if two types of construction lifts look the same, they have different uses

Using the wrong type of lift can put your safety and well-being at risk

There are defined steps you can take to choose the right lift for your needs

Elevators - Finding the Perfect Fit with Insights into Pro's ...

In vertical transportation systems, selecting the appropriate elevator type is a critical decision influenced by various factors ranging from building height to design preferences.

Having previously explored the multifaceted factors influencing elevator costs in Nigeria, it becomes paramount to shift our focus to the array of elevator types available.

This analysis aims to highlight the advantages and disadvantages of four primary elevator types: Hydraulic, Traction, Machine-Room-Less (MRL), and Pneumatic Vacuum systems. Each of these types exhibit distinctive attributes that significantly influence their suitability for various contexts.

An evaluation of these elevator types becomes indispensable, taking into account critical factors such as building specifications, available space, and budgetary constraints. This examination will be instrumental in the decision-making process, aligning the chosen elevator type with the specific requirements of each unique project.

Without further ado, let's transition into the heart of our discussion, where we navigate the various elevator options and equip you with the knowledge needed to make sound decisions regarding elevator projects.

Hydraulic Elevators:

Advantages:

Cost-Effective: Hydraulic elevators are often more economical to install, making them a popular choice for low to mid-rise buildings.

Simple Installation: They are relatively easier to install compared to other types of elevators.

Smooth Ride: Hydraulic elevators typically provide a smooth and quiet ride.

Disadvantages:

Limited Height: Hydraulic elevators are not well-suited for very tall buildings due to their height limitations.

Space Requirements: They require a machine room for housing the hydraulic pump and motor.

Traction Elevators:

Advantages:

High Rise Capability: Traction elevators are suitable for tall buildings and skyscrapers.

Efficient: They are generally more energy-efficient than hydraulic elevators.

Variable Speed: Traction elevators often have variable speed options, providing better control and efficiency.

Disadvantages:

Higher Initial Cost: Traction elevators are typically more expensive to install than hydraulic systems.

Complex Installation: The installation process can be more complex and time-consuming.

Machine-Room-Less (MRL) Elevators:

Advantages:

Space-Saving: MRL elevators eliminate the need for a separate machine room, saving space.

Energy-Efficient: They are often designed to be more energy-efficient, reducing overall operational costs.

Modern Aesthetics: MRL elevators can have a sleek and modern design.

Disadvantages:

Limited Weight Capacity: MRL elevators may have restrictions on weight capacity compared to traditional traction systems.

Maintenance Accessibility: Accessibility for maintenance can be challenging since components are housed within the shaft.

Pneumatic Vacuum Elevators:

Advantages:

Unique Design: Pneumatic elevators use air pressure to move the cabin, providing a distinctive design.

Minimal Space Requirements: They often require less space than traditional elevators.

360-Degree Views: Some models offer panoramic views as the cabin is made of transparent materials.

Disadvantages:

Limited Load Capacity: Pneumatic elevators are generally designed for smaller passenger loads.

Noise Levels: The movement of air in the system can produce noise during operation.

Each type of elevator has its own set of advantages and disadvantages, and the choice depends on factors such as building height, space availability, budget considerations, and design preferences. It is essential to carefully evaluate these factors to determine the most suitable elevator type for a particular application.

It is also important to note that elevators are not readily available as off-the-shelf items. Consequently, the duration from manufacturing to installation and commissioning is a minimum of six months.

Now go ahead and make that informed decision by speaking to our professional team on 08035354561 or 07068971010.

PPC Building Services Engineering...Optimizing Building Performance!

Trusted to provide Elevators | Escalators | MEP | ELV | HVAC | Access Control | Perimeter Security | Identity Solutions | Street Lighting and much more.

Celebrating #30YearsofEngineeringExcellence

• Lagos • Abuja • Port Harcourt • Warri • Enugu • Yenagoa

Want more information on small boom lift? Feel free to contact us.

Explore more:What class is a propane forklift?

Streamline Your Packaging Process with Full Automatic Folder Gluer

Which Six Groups Feeder and Straightener Machine is Best for High-Speed Metal Stamping?

Choosing the Best: Double Acting vs Single Acting Cylinders

Which High Speed Packaging Equipment is the Best Investment for My Company's Purchase Stage?

Which Industries Benefit Most from Robot-type Automatic Screw Driving Machine?

Which SMT transmission equipment offers the best value for a seamless purchase process?