Why Industrial Cylindrical Grinding Machines Are Essential

Industrial cylindrical grinding machines are essential for a variety of reasons in the manufacturing industry. .

One of the primary reasons why these machines are indispensable is their ability to achieve high levels of precision and accuracy in the grinding process. By using a cylindrical grinding machine, manufacturers can create highly precise cylindrical shapes with tight tolerances, ensuring that their products meet the required specifications. This level of precision is crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation from the desired dimensions can have serious consequences.

Furthermore, industrial cylindrical grinding machineindustrial cylindrical grinding machines are essential for improving efficiency and productivity in the manufacturing process. These machines are capable of grinding large volumes of materials quickly and consistently, reducing the time it takes to produce finished parts. This increased efficiency not only saves time but also reduces costs, making the manufacturing process more cost-effective in the long run.

In addition to precision and efficiency, industrial cylindrical grinding machines also offer versatility and flexibility in the manufacturing process. These machines can be used to grind a wide range of materials, including metals, ceramics, and composites, making them suitable for a variety of applications. Whether it's creating prototypes, repairing damaged parts, or producing high-volume components, cylindrical grinding machines can adapt to different needs and requirements.

Explore more:Which is the Better Transportation Method: Cable Car or Ropeway?

How does a fixed grip chairlift work?

What are the parts of aerial work platform?

How to design an efficient lithium battery module assembly line?

What size is a LN2 tank?

Demystifying the Cone Crusher Machine: Your Guide to Understanding its Function and Benefits

Advantages and Applications of CNC Gang Tool Lathes

Moreover, the high level of automation and advanced technology found in modern cylindrical grinding machines makes them even more essential in the manufacturing industry. These machines are equipped with sophisticated controls and monitoring systems that allow operators to optimize the grinding process for maximum efficiency and quality. Additionally, features such as automatic tool changers, in-process measurement, and adaptive control systems enhance the accuracy and performance of the machines, further increasing their value in the production process.

In conclusion, industrial cylindrical grinding machines are essential tools in the manufacturing industry due to their unparalleled precision, efficiency, versatility, and advanced technology. These machines play a crucial role in ensuring the quality and consistency of finished products, improving productivity and reducing costs for manufacturers. As technology continues to advance and demands for high-quality precision components grow, the importance of industrial cylindrical grinding machines will only continue to increase.

Contact us to discuss your requirements of cnc internal grinding, three roll bending. Our experienced sales team can help you identify the options that best suit your needs.

Explore more:What are the disadvantages of horizontal storage tanks?

AT&T Store: Unveiling the Best Tech Deals!

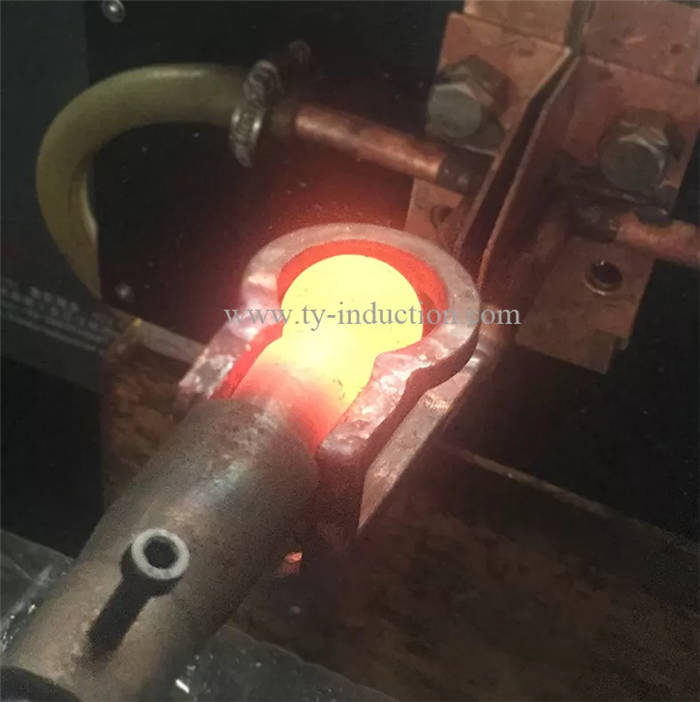

Revolutionizing Metal Hardening with Ultra-High Frequency Induction Heating Machines

The Future of Electronics Manufacturing: The Soldering Robot

Which industries can benefit from smart logistics robots?

Unveiling Precision Engineering: The 6-Axis 8-Module CNC Gear Hobbing Machine

How Are The Chips Packing Machine Working?