Why not use slip on flanges?

Why not use slip on flanges? Slip on flanges are a type of flange that can be slipped onto the pipe before welding. Although they may seem convenient, there are several reasons why they may not be the best choice for certain applications.

Firstly, slip on flanges have a lower pressure rating compared to other types of flanges such as weld neck or socket weld flanges. This is due to the fact that slip on flanges are not as strong or rigid as other types. They are more prone to leakage and can be a safety concern in high-pressure applications.

The second reason is the lack of structural support provided by slip on flanges. Unlike weld neck flanges, which have a long tapered hub, slip on flanges do not provide any additional support to the pipe. This can be a problem in situations where the pipe is subjected to bending, vibration, or thermal expansion. The lack of support can result in pipe misalignment or even pipe failure.

What are the four types of metal tubing?

Which Stainless Steel Decoration Screen Sparks Creativity?

Explained: Stator & Rotor in Motors – Essential Components & Working Principles

Revolutionizing Manufacturing: How Custom Carbide Tooling Shapes the Future?

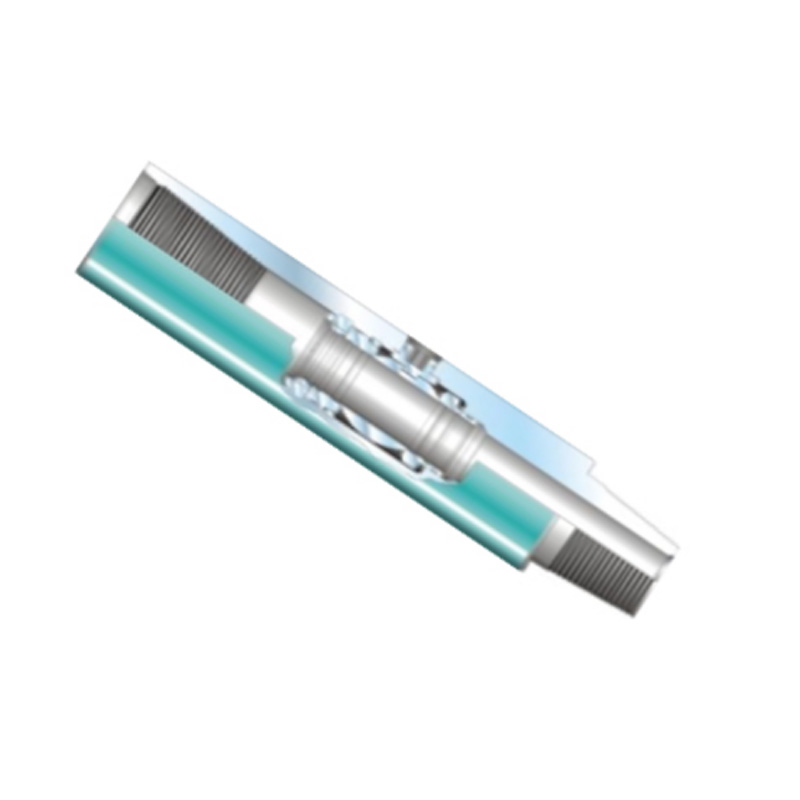

The Ultimate Guide to Pup Joint in Oil and Gas Industry

How are slip on flanges connected?

How much does it cost to injection mold a part?

Furthermore, slip on flanges are not suitable for applications with extreme temperature variations. The welding process used to attach slip on flanges can create a localized heat-affected zone on the pipe, which can be susceptible to thermal fatigue. In contrast, weld neck flanges are designed to distribute the stress caused by thermal expansion more evenly, reducing the risk of failure.

Another point to consider is the cost-effectiveness of slip on flanges. While they may be cheaper initially, the long-term costs can be higher due to potential maintenance and replacement needs. With their lower pressure rating and lack of structural support, slip on flanges may require more frequent inspections and repairs, resulting in increased downtime and expenses.

In conclusion, slip on flanges may not be the best choice in certain applications due to their lower pressure rating, lack of structural support, vulnerability to thermal fatigue, and potential long-term costs. It is important to carefully assess the specific requirements and conditions of each project before selecting the appropriate type of flange. Considering alternatives such as weld neck or socket weld flanges can provide better performance, reliability, and safety in the long run.

For more information, please visit weldolet, copper nickel pipe fitting, weldolet flange.

Explore more:Unveiling the Power of Hydraulic Rotating Cylinders: Boost Efficiency & Master Heavy Machinery

Ultimate Ornamental Iron Parts Guide: Enhance Decor with Elegance

Porous Tube: Effective Filtration Solution for Pure Water? Explore Now!

What is the maximum size of stainless steel sheet?

What are the advantages of riveting?

What are the advantages of purchasing electric subsurface safety valves?

What are the advantages of purchasing wrought or forged products for businesses in the B2B market?