Exploring the Explosive Differences: Nitrocellulose Plant vs Regular Chemical Plant

Exploring the Explosive Differences: Nitrocellulose Plant vs Regular Chemical Plant.

Have you ever wondered how different a nitrocellulose plantnitrocellulose plant is from a regular chemical plant? One thing is for sure; they both produce chemicals of various kinds. However, the difference lies in the structure, process, and the required level of safety procedures. In this article, we will explore the explosive differences between a nitrocellulose plant and a regular chemical plant.

Nitrocellulose Plant: What's It All About?

A nitrocellulose plant is a factory that produces nitrocellulose. Nitrocellulose is a highly flammable, semi-synthetic material that can be used for a variety of purposes. These can range from creating paper-based materials to making explosives. Nitrocellulose is made by treating cellulose (usually derived from wood) with nitric acid. This process results in the cellulose becoming highly flammable and explosion-prone, making it a popular choice for producing explosives.

Structure and Safety Procedures.

In order to produce nitrocellulose safely, a nitrocellulose plant must be equipped with specific safety procedures and structures. These include electrical safety systems to prevent spark generation, explosion-proof lighting, careful monitoring of all raw materials and finished products, as well as carefully managed ventilation systems. The production process itself is usually carried out using specialized equipment that minimizes the risk of ignition, such as vacuum drying ovens.

Regular Chemical Plant: How is it Different?

Explore more:Why is theophylline no longer used?

Best Artificial Grass Around Pools: Complete Buyer's Guide

Questions You Should Know about methyluracil ointment factory

High Purity Magnesium Oxide Market Competition (2024- ...

Key Questions to Ask When Ordering High Temp Silicone Oil

How to Choose Cas 2602-34-8: A Step-by-Step Guide

Our Blog - Demolition Powder

A regular chemical plant, on the other hand, is a factory that produces a variety of chemicals such as fertilizers, pesticides and pharmaceuticals. The chemicals produced in a regular chemical plant are not as flammable and explosive as those produced in a nitrocellulose plant. Due to this difference, the safety procedures in a regular chemical plant are somewhat different from those in a nitrocellulose plant.

Structure and Safety Procedures.

A regular chemical plant still requires plenty of safety measures to ensure that the workers and products remain safe. While the process carried out in a regular chemical plant doesn't involve as many explosives, the chemicals themselves can still be dangerous if not handled properly. For instance, a regular chemical plant may require an explosion-proof building, but the procedures for monitoring, handling, and storing chemicals may vary from those carried out in a nitrocellulose plant.

In Summary.

In conclusion, while nitrocellulose and regular chemical plants are both manufacturing plants dedicated to producing chemicals, the process, structure, and safety procedures required for each type of plant are vastly different. A nitrocellulose plant needs to have specialized equipment, ventilation systems, and constant monitoring of raw materials, while a regular chemical plant may require specialized buildings and proper handling of chemicals. Both types of plants serve specific needs, but both require proper safety measures to ensure a safe working environment for their workers.

Do you have any questions or comments about nitrocellulose or regular chemical plants? Contact us today for more information about chemical production or if you're interested in becoming a supplier.

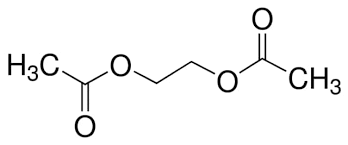

For more acetic acid vs acetone, Methyl Methacrylate Productioninformation, please contact us. We will provide professional answers.

Explore more:Unlocking Benefits of 3-Ureidopropyltriethoxysilane Solutions

The Best Places to Buy Anatase Tio2 Online and In-Store

Paints and Dye To Use On Synthetic Fabrics

Key Questions to Consider When Sourcing Re-dispersible Polymer Powder for Tile Adhesive Exporters

How Should We Rethink ETICS with RDP?

How to Save Money When Buying Pharma Magnesium Oxide ...

What is the mechanism of action of redispersible polymer ...