How is MEG production impacting industries?

How is MEG Production Impacting Industries?

MEG or monoethylene glycol is an essential chemical compound widely used in industries such as textile, packaging, automotive, and construction. MEG is traditionally produced from fossil fuel sources, but recent developments have enabled its production from renewable resources such as biomass and waste streams. The growing demand for MEG and the shift towards sustainable production has a significant impact on industries and their supply chains. In this article, we will explore how MEG productionMEG production is impacting industries and driving sustainability efforts.

The Growing Demand for MEG.

MEG is used as a raw material in the production of polyester, which is widely used in the textile industry. It is also used in the production of PET bottles and packaging, antifreeze, and as a solvent in various applications. The increasing demand for polyester fibers and PET bottles due to the rising population and urbanization is driving the demand for MEG. According to a report by Grand View Research, the global MEG market size was valued at USD 25.9 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2020 to 2027.

The Impact on the Textile Industry.

The textile industry is one of the largest consumers of MEG as it is used in the production of polyester fibers. The use of MEG in the textile industry has enabled the production of polyester fibers with improved properties such as strength, elasticity, and wrinkle resistance. However, the traditional production of MEG from fossil fuels is highly carbon-intensive, resulting in significant greenhouse gas emissions. The shift towards sustainable MEG production from renewable resources such as biomass and waste streams is enabling the textile industry to reduce its carbon footprint and meet sustainability goals.

The Sustainability Efforts in the Packaging Industry.

The packaging industry is another major user of MEG as it is used in the production of PET bottles and packaging. The growing demand for PET bottles due to the increasing consumption of bottled water, soft drinks, and other beverages has led to concerns about the environmental impact of plastic waste. The packaging industry is actively working on sustainability efforts to reduce plastic waste by introducing recycled materials and increasing the use of bio-based materials, including sustainable MEG, which can be produced from renewable resources such as sugarcane and corn.

Explore more:The Phenol Alkylation Plant Revolutionizes Chemical Industry

What is copper sulfate mainly used for?

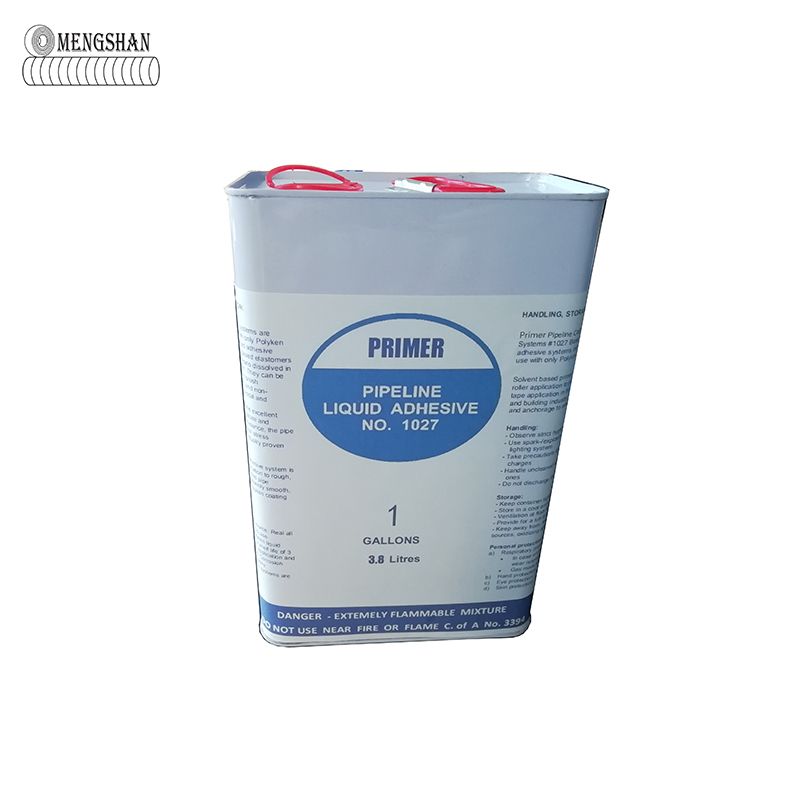

What is a liquid adhesive?

Unlocking the Potential of Isobutane: A Comprehensive Guide

What Are Polypropylene Fibres Used For?

Applications of Matting Powder in Leather Products

The Role of the Methyl Acetate Plant

The Role of Automotive and Construction Industries.

MEG is also used as an antifreeze agent in the automotive industry, where it helps to prevent engine overheating and freezing. The use of MEG in the automotive industry has enabled the production of more fuel-efficient vehicles, reducing their environmental impact. Furthermore, MEG is used as a coolant in the construction industry in the production of concrete and mortars. Sustainable MEG production is helping the construction industry to meet sustainability goals and reduce its carbon footprint.

Conclusion.

MEG production has a significant impact on various industries and their supply chains. The growing demand for MEG and the shift towards sustainable production methods are enabling industries to reduce their carbon footprint and meet sustainability goals. The textile industry is successfully producing polyester fibers with improved properties and reducing its environmental impact through the use of sustainable MEG. The packaging industry is also taking steps towards sustainability efforts by introducing recycled and bio-based materials. The automotive and construction industries are benefiting from the use of MEG in the production of more efficient and sustainable products. Sustainable MEG production is driving the sustainability efforts of industries and helping them to achieve a sustainable future.

Contact Us.

For more information about MEG production and sustainability efforts, please contact us.

Are you interested in learning more about mek substitute, air separation technologies supplier? Contact us today to secure an expert consultation!

Explore more:Elevate Your Interiors with Luxurious Velvet Effect Wall Paint

Sodium Cumene Sulfonate: Unveiling the Versatile Surfactant

What is the purpose of anti rust lubricant spray?

What are the advantages of PU adhesive?

WHAT ARE THE PROPERTIES OF SURFACTANTS?

Can You Use Hyaluronic Acid Every Day?

Does Nail Free Adhesive Damage the Wall?