What is Formworks Button Magnet and Why Do We Use Them?

Magnets and magnetic systems – Magnets for formworks

We have a wide range of magnets and formwork holders and systems for precast concrete industry. Nowadays, the use of magnets is widespread in all precast factories, due to the efficiency and time reduction they allow.

Contact us to discuss your requirements of Formworks Button Magnet. Our experienced sales team can help you identify the options that best suit your needs.

The use of modern formwork magnets makes it possible to eliminate welding on the formwork tables, increasing their service life of the tables and greatly reducing the preparation time. This system also avoids the grinding process when removing welds.

Explore more:Exploring the Benefits of Using SCM440 Steel Bar

How to Choose 20 Mesh Mica Powder: A Step-by-Step Guide

How to Choose 301ln Box Section: A Comprehensive Guide

Decoration Profiles: Enhancing Spaces with Style and Functionality

Are Glass Beads the Solution for Effective Road Marking?

What is Welded Razor Wire Mesh used for?

Graphite Crucible: A Comprehensive Guide

If you want to learn more, please visit our website strong Loaf Neodymium Magnet.

CONAC | Push Button Magnet

Push Button Magnet

The push button magnet is primarily used in side rails and blockouts but can be applied to a wide variety of forming scenarios including custom forms. The powerful internal magnet, available in a range of adhesion force capacity, can be applied to the steel form by pressing down on the centered button, and is released from the steel with the same method, allowing for easy and convenient usage and long term reusability.

Are you interested in learning more about Shuttering Magnet Factory? Contact us today to secure an expert consultation!

The Benefits and Features of Stainless Steel Window Insect Screens

What Are The Reasons for Failure of Wear Plates?

What is a Low Fin Tube? Understanding its Significance in Heat Exchangers

Is alloy steel better than stainless steel?

What is Alloy Steel Pipe Used For? A Comprehensive Guide

How are ductile iron pipes and fittings installed?

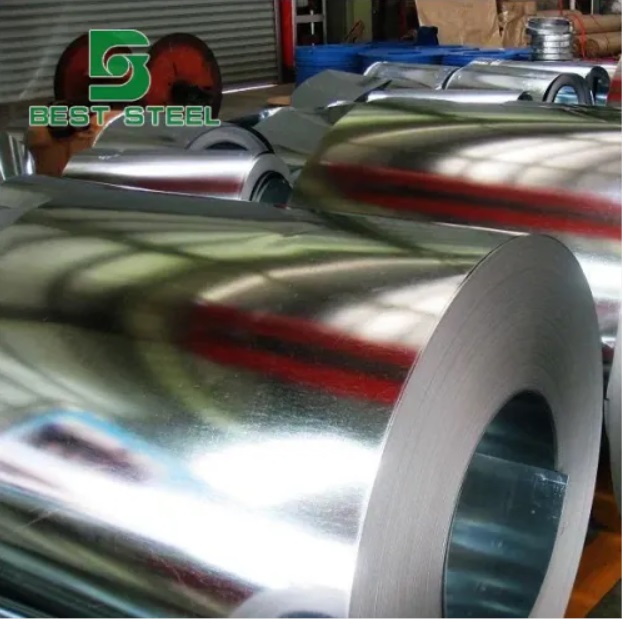

Hot-Dipped Galvanized Coil: Unleashing the Power of Corrosion Resistance